Sixth, We Tried to Use a 3D Printer to Realize Our Creations.

Article Catalog

- Assembly Printing

- Parts Printing

- 3D Printing Advanced Experiment

- 3d Printing Frontiers

Assembly Printing

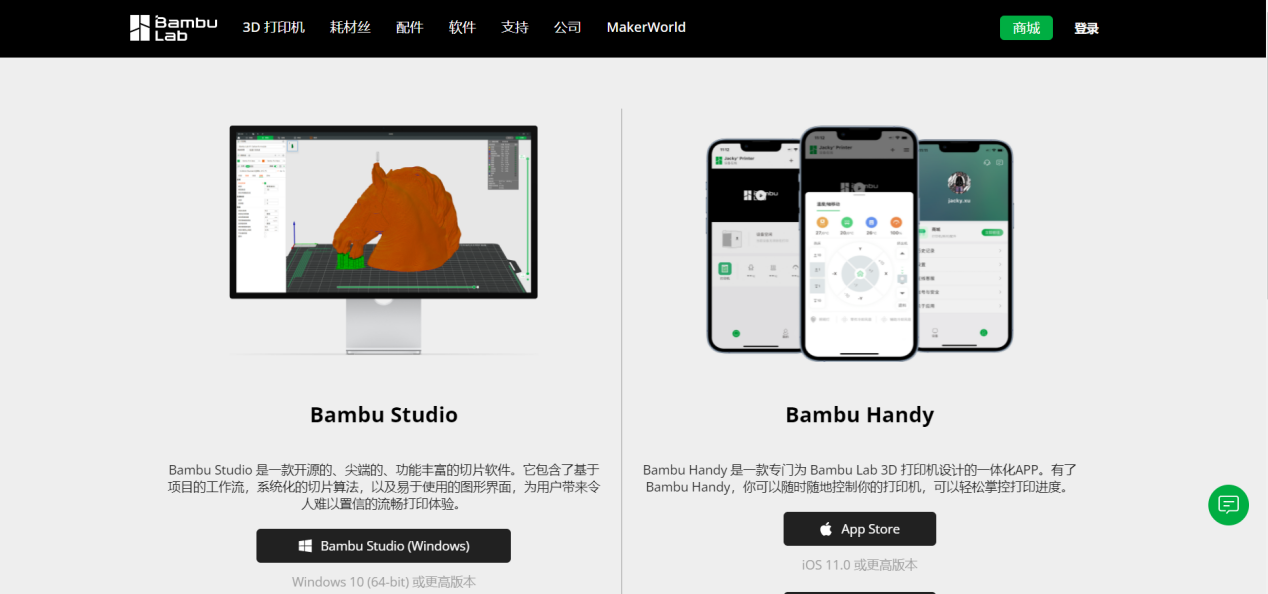

Download the software at the following website: https://bambulab.com/zh/download

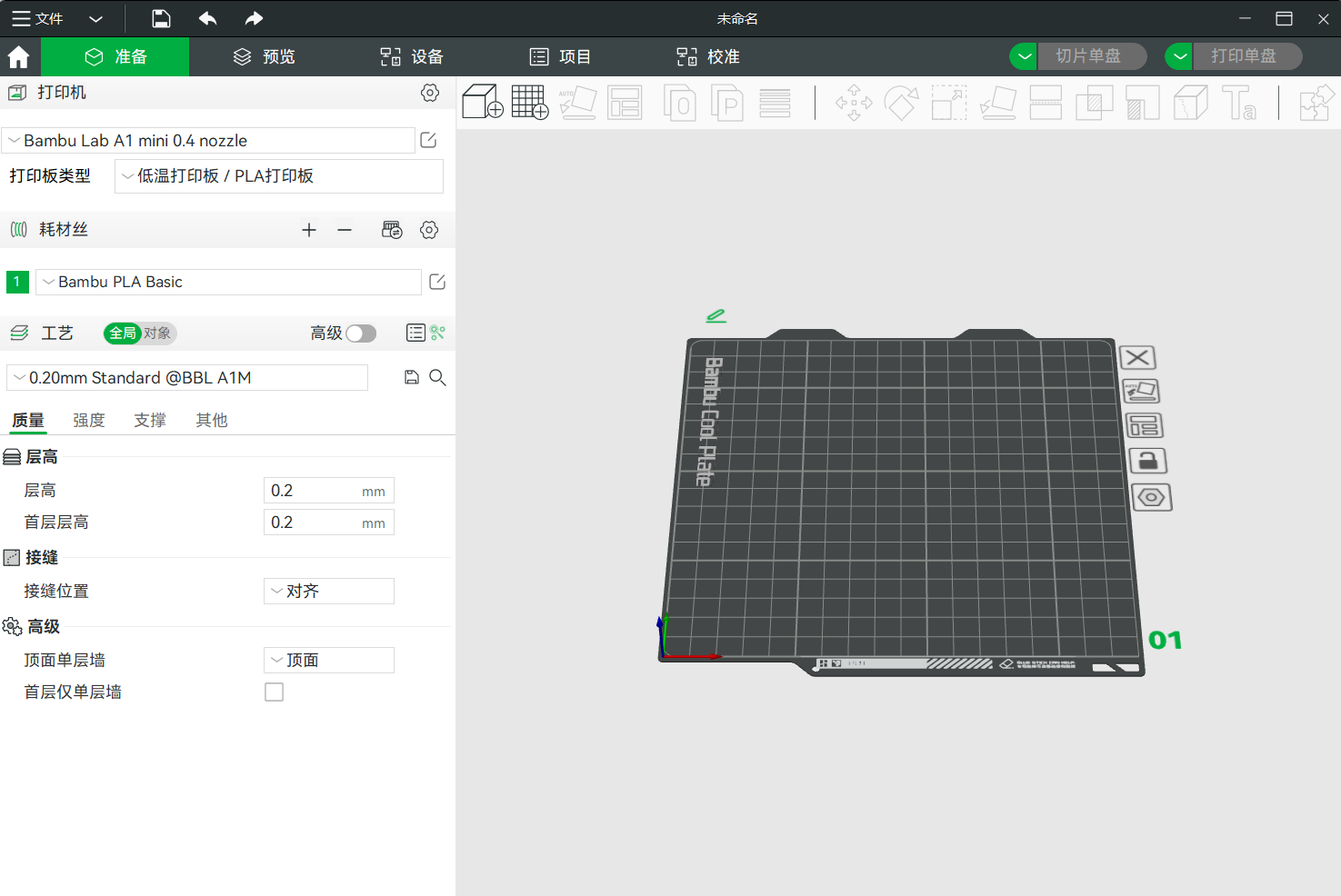

Software installation completed.

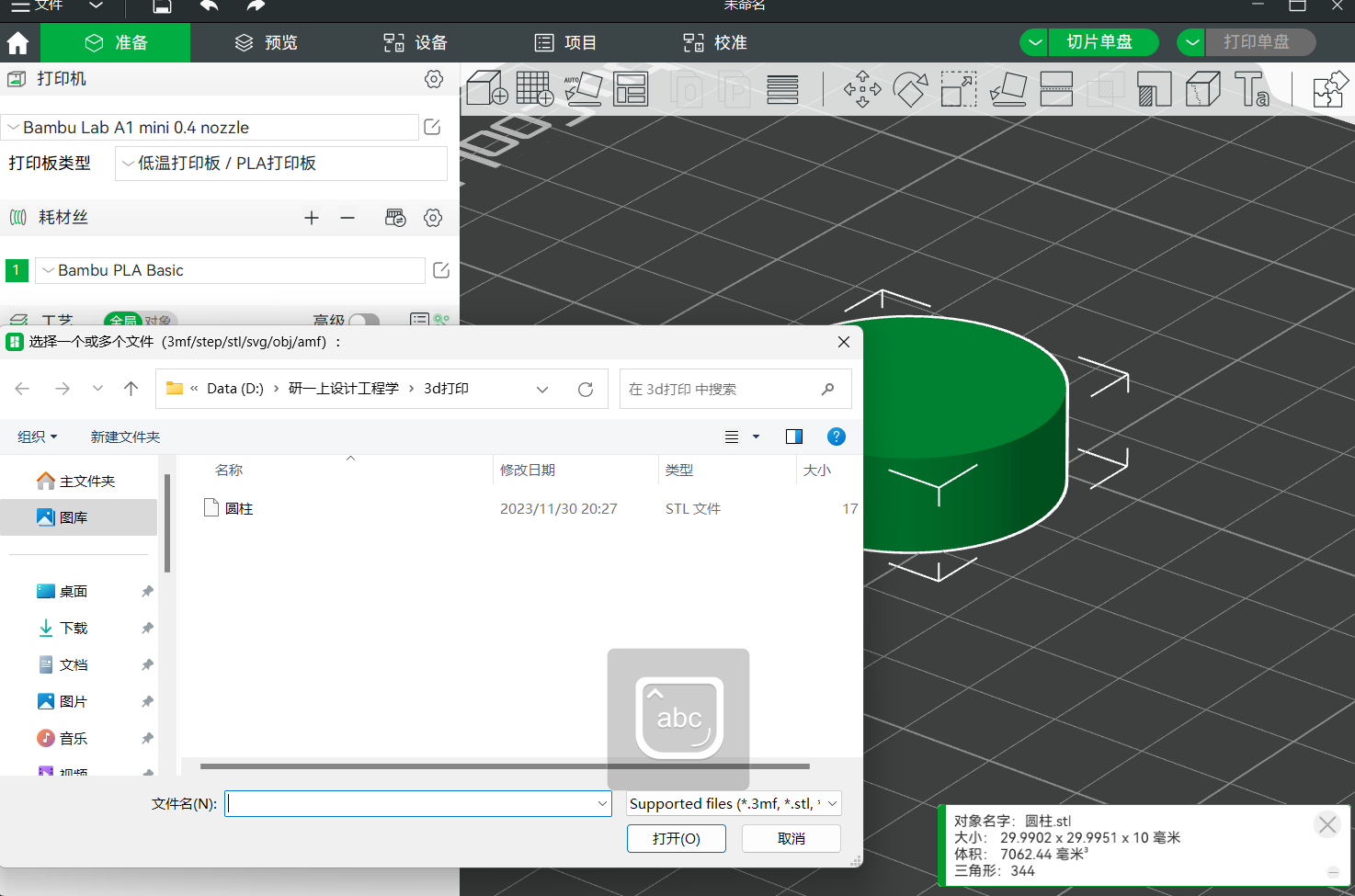

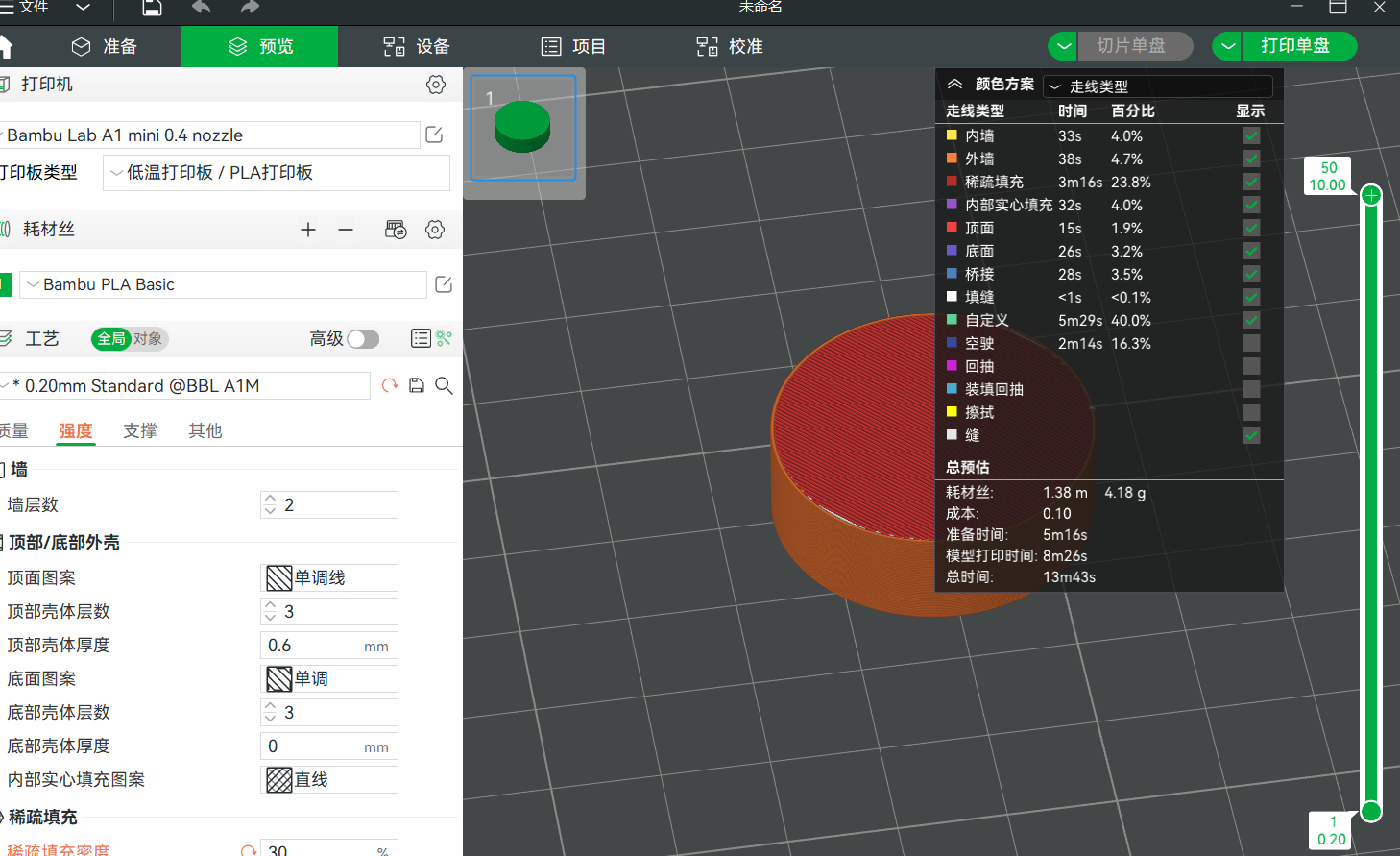

Import the cylinder model.

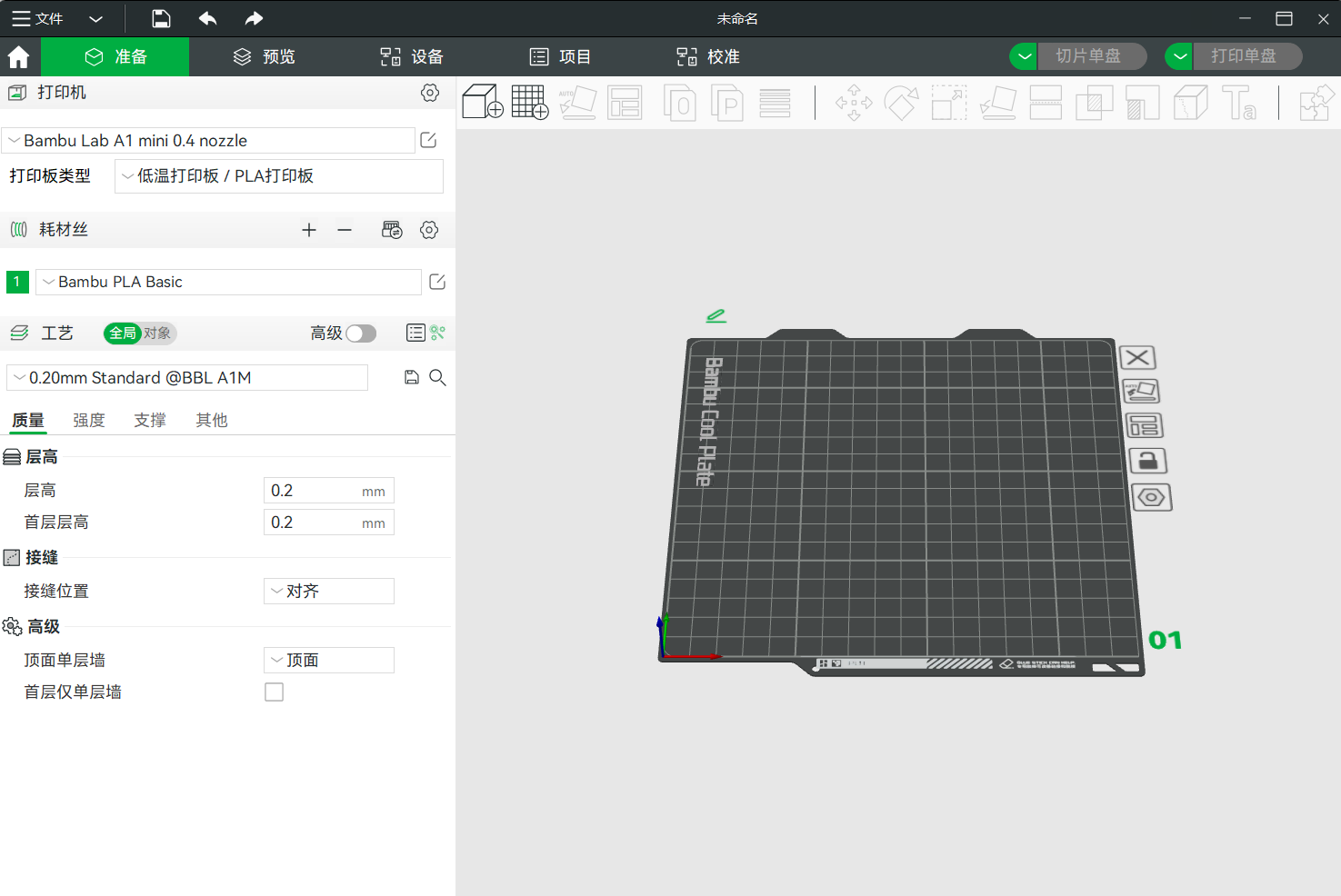

Change the print parameters.

The 3D printing of the core parameters:

| NAME | DATA |

|---|---|

| Single Layer Thickness | 0.2mm |

| Model Wall Thickness | 2 |

| Bottom Wall Thickness | 4.5 |

| Bottom Layer Thickness | 0.3mm |

| Fill Rate | 15% |

| Support Fill Rate | 30% |

| Support Structure Angle | 45° |

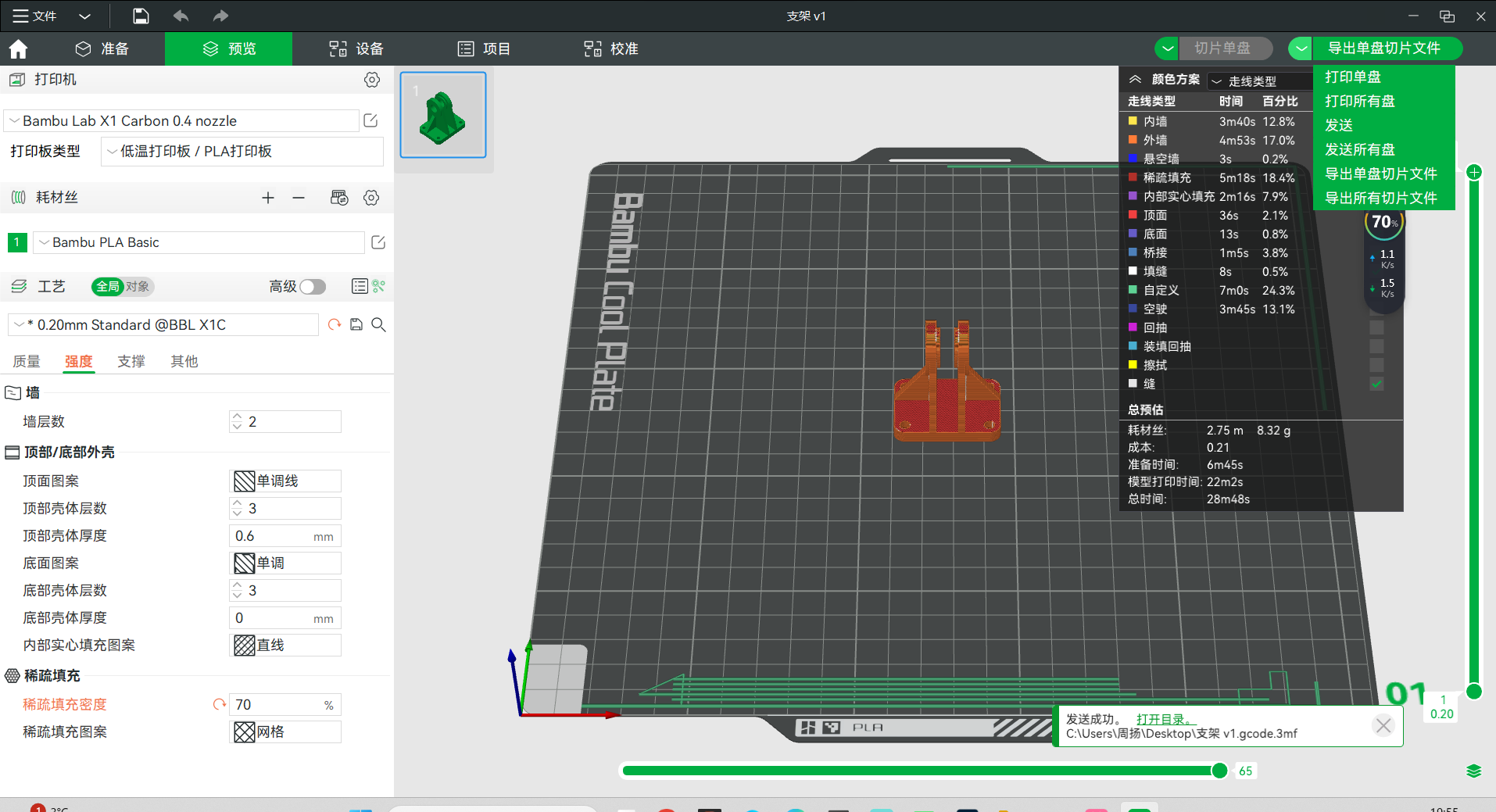

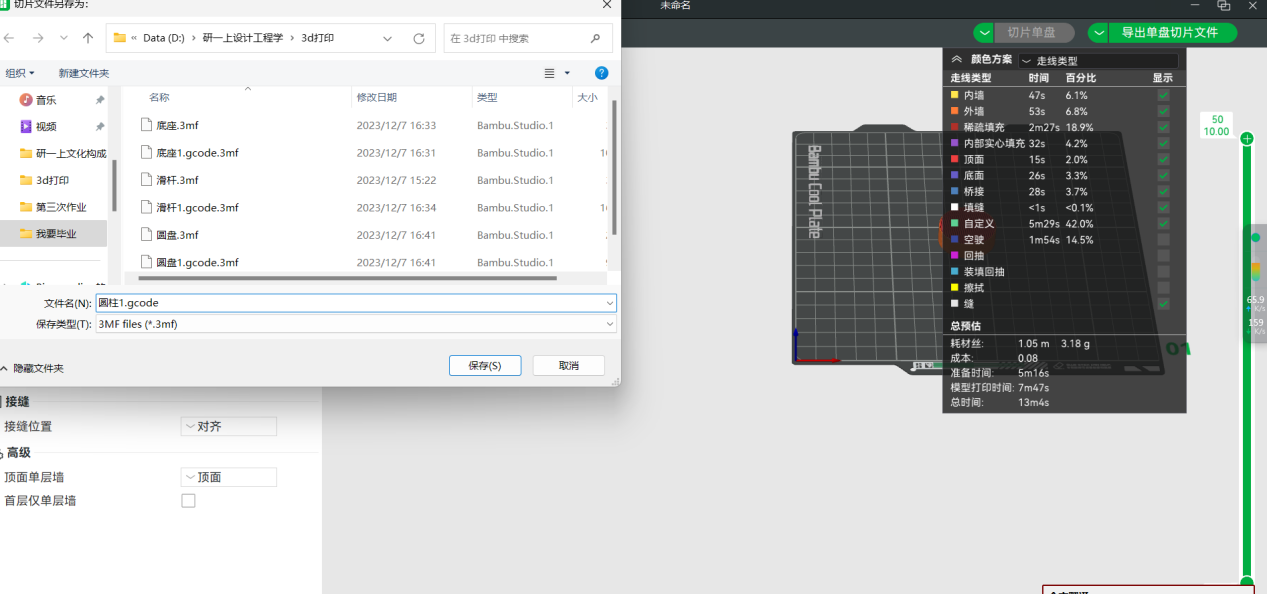

When finished, the slicer enters the Preview pane, which displays the appearance of the slice model after processing the. 3 mf file. The histogram on the right will also display the print time information for each print parameter.

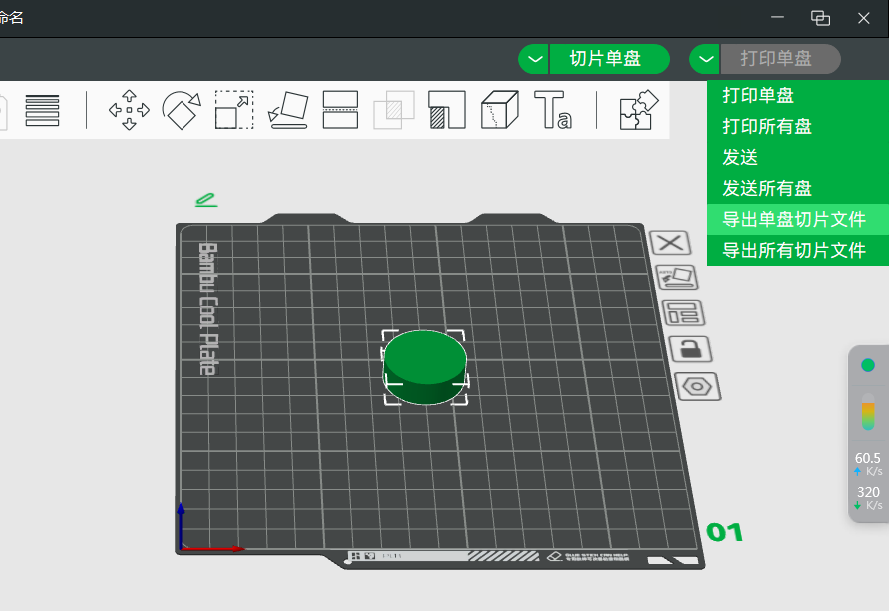

Click on “slice single disk”

Click the arrow on the left of Print Plate to select Export File.

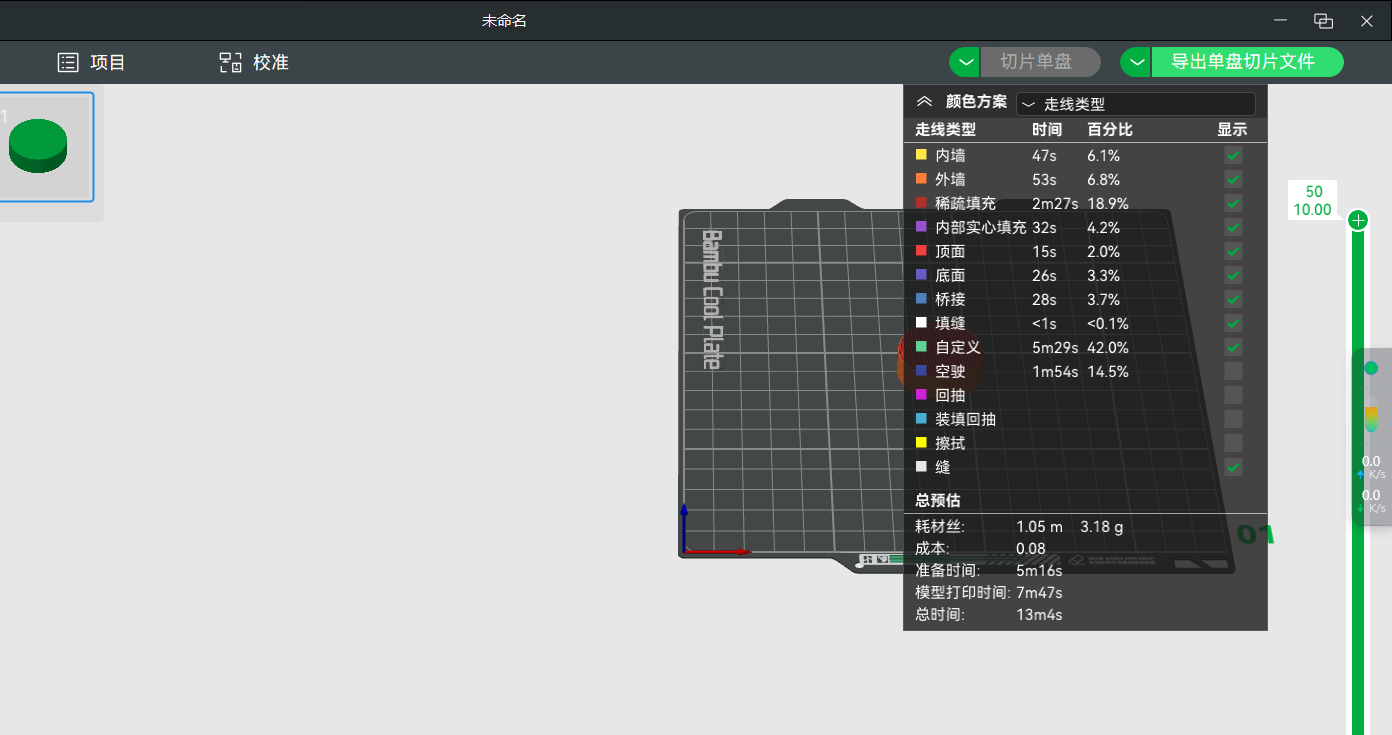

Click Export Single Dislide File.

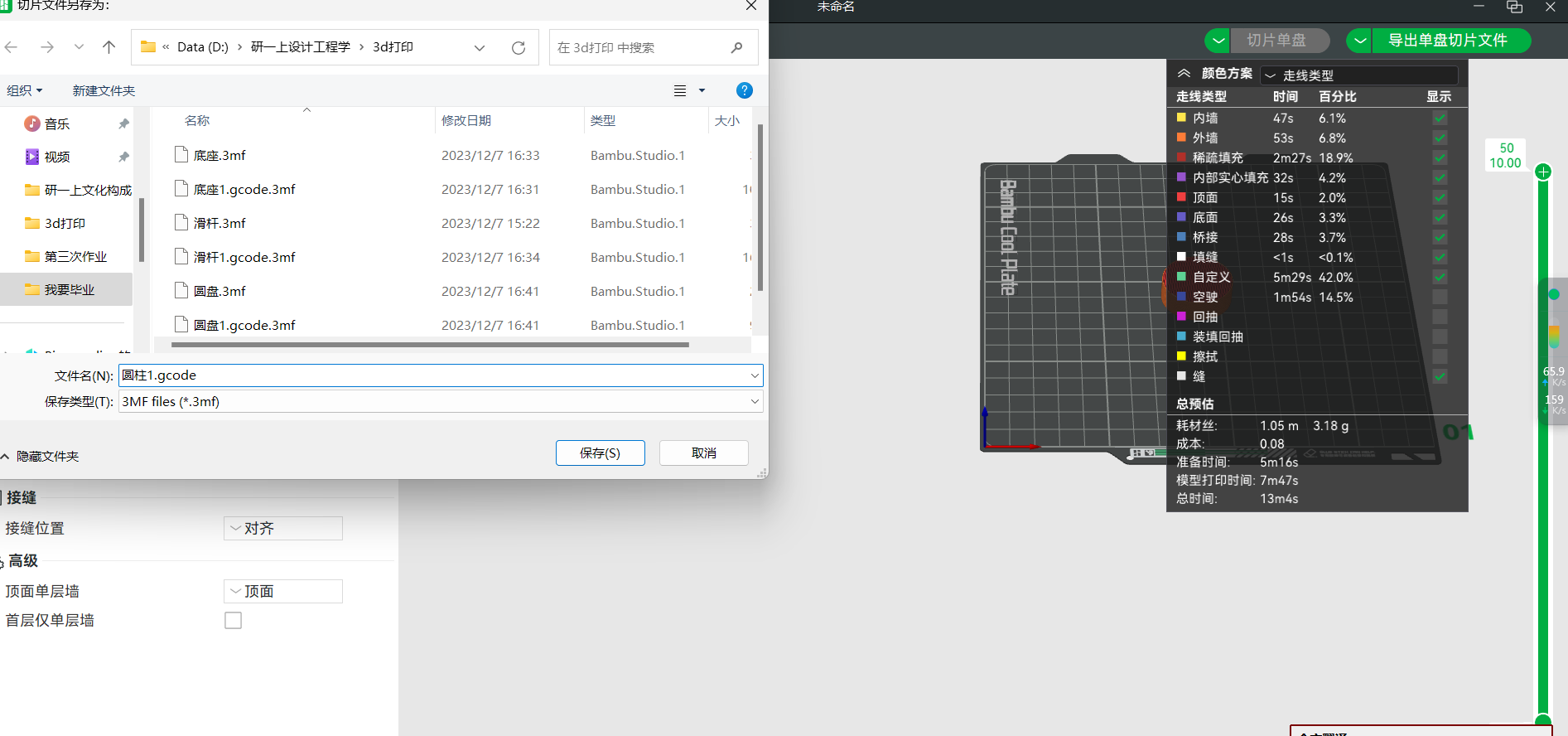

Save the gcode.3mf file

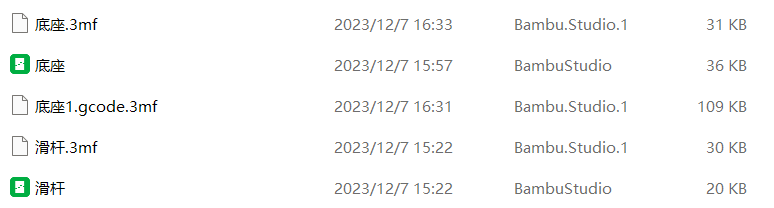

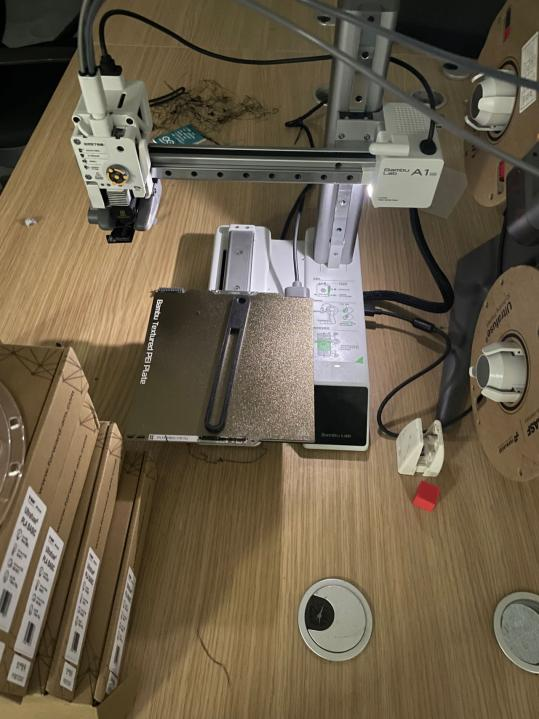

Store the files in the printer’s SD card to print on the printer, manipulate the three parts exported from the fusion360, convert them into files readable by printers like gcode.3mf, and store them in the SD card of the printer.

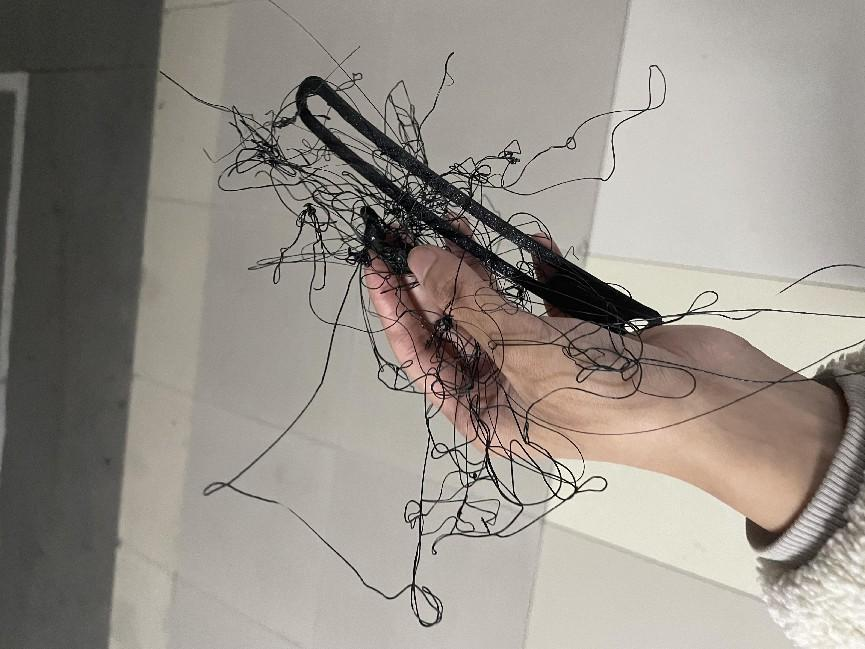

Starting printing, and the print part is detached.

It turned out that during the 3D printing process, the parts fell off the hot bed, resulting in the printing failure, and the printing succeeded after spraying the adhesive on the hot bed.

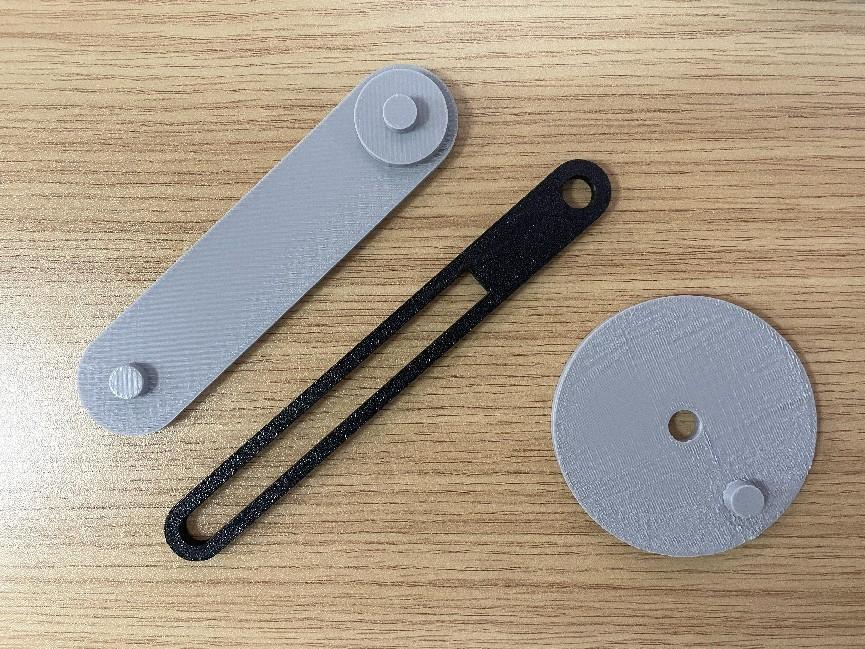

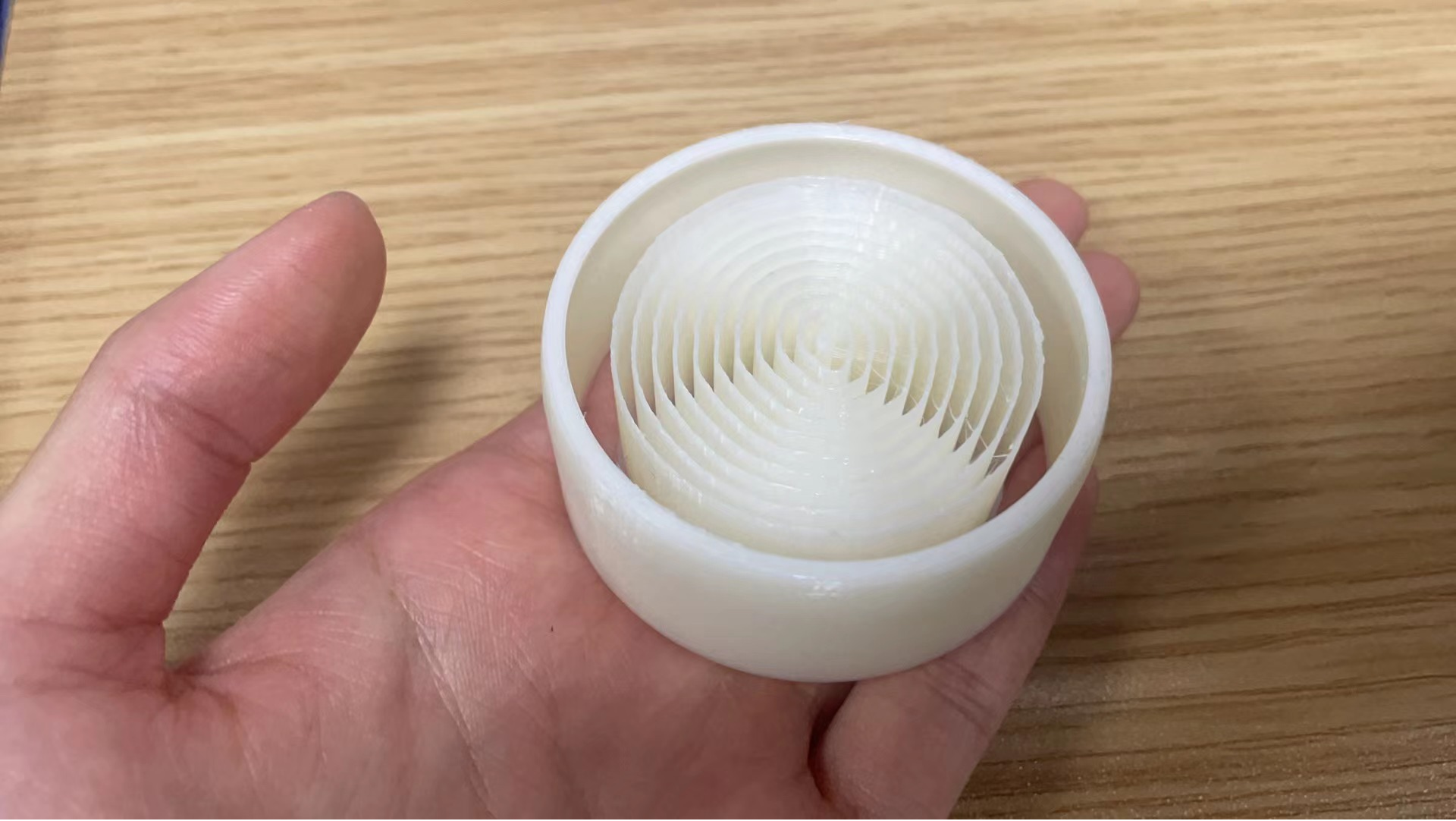

Spray the adhesive solved the problem and printed three parts.

Grit using sandpaper.

Comparison diagram before and after grinding

Assemble the parts and complete the production

Reality Assembly Sport GIF picture

Parts Printing

Download the software at the following website: https://bambulab.com/zh/download

Software installation completed.

Download the model at the following website:https://m.youtube.com/watch?v=QQKxFGbZ5jw&pp=ygUKZnVzaW9uIDM2MA%3D%3D

Import the cylinder model.

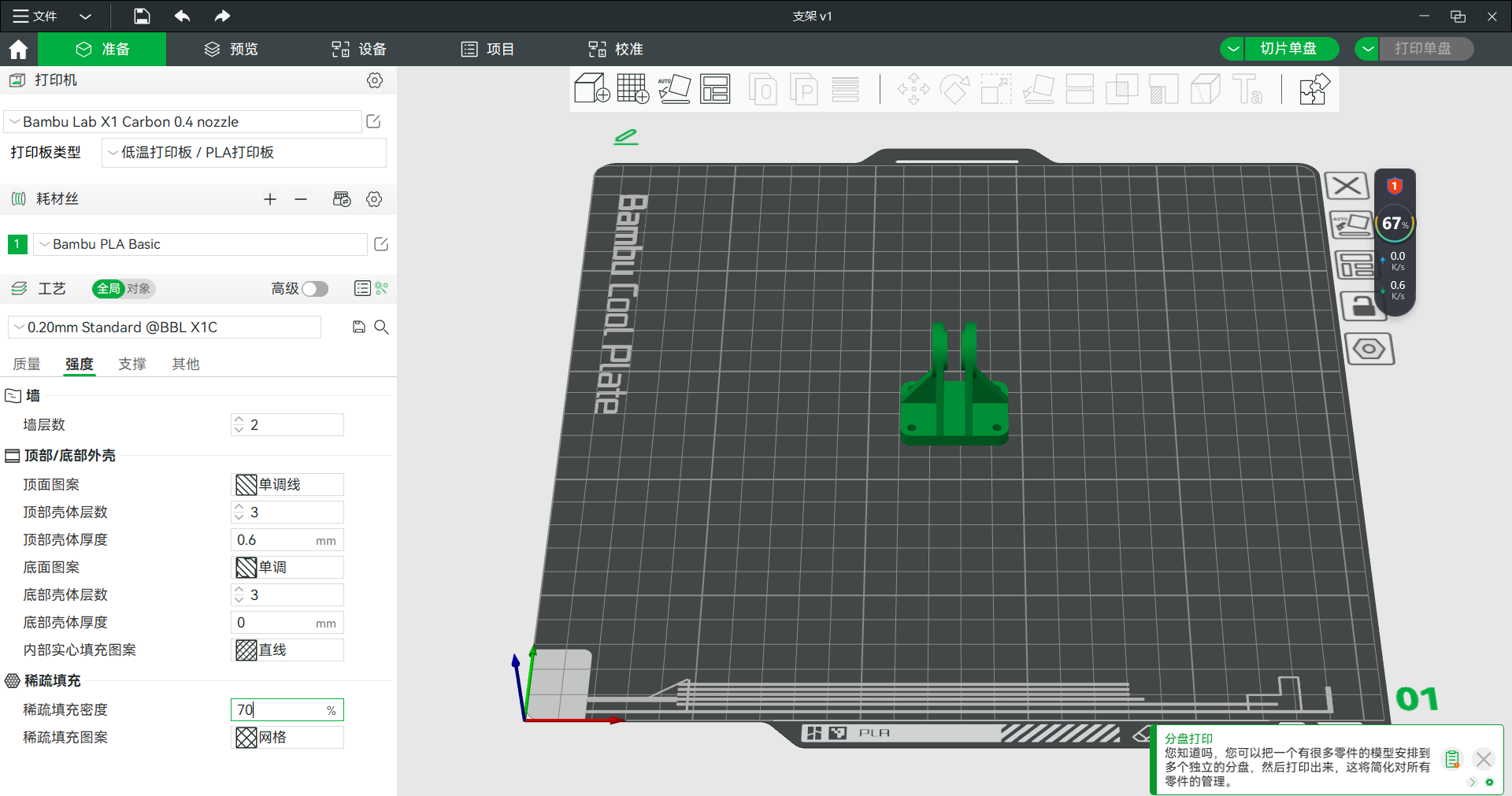

Change the print parameters.

The 3D printing of the core parameters:

| NAME | DATA |

|---|---|

| Single Layer Thickness | 0.2mm |

| Model Wall Thickness | 2 |

| Bottom Wall Thickness | 4.5 |

| Bottom Layer Thickness | 0.3mm |

| Fill Rate | 15% |

| Support Fill Rate | 30% |

| Support Structure Angle | 45° |

When finished, the slicer enters the Preview pane, which displays the appearance of the slice model after processing the. 3 mf file. The histogram on the right will also display the print time information for each print parameter.

Click Export Single Dislide File.

Save the gcode.3mf file

Start to print.

Finish

3D Printing Advanced Experiment

We also did some creative 3D printing materials, using a lab printer, and because we love the animation of Rick and Morty, 3D made one of the characters, and assembled the spray paint.

Also at Christmas, using a lab printer to print the dolls.

3d Printing Frontiers

01 Materials and Technical Advances

Nanoscale transparent glass 3D printing technology: The J. Bauer team at California State University has developed a low-free 3D printed silicon glass technology that enables the manufacture of complex transparent molten quartz glass nanostructures. This technique mainly uses acrylate functionalized polyfacial oligosiloxane (POSS) resin for free sintering and two-photon polymerization of molten silica nanostructure.

High-precision 3D printing silicone: The Thomas E Angelini team at the University of Florida has developed a PDMS-based 3D printing method that can accurately print complex and detailed structures. This method mainly uses supporting materials made from silicone oil emulsion, allowing the use of mature silicone formulations to make micron-scale complex structures.

Machine learning-assisted 3D printing: The Tao Sun team at the University of Virginia uses machine learning to detect pore formation from thermal features to avoid building failed components due to high porosity.

02 3D Printing Industry Applications

Market size: The global 3D printing market size will reach us $12.758 billion in 2020, an increase of 7.5% compared with 2019. The market size of 3D printing services is about 7.454 billion US dollars, accounting for 59.29%, indicating that services have become an important driving force for the development of the industry.

Material market: The global 3D printing materials market size in 2020 is us $2.105 billion, including metal and polymer powder, liquid resin, silk and grain material, etc.

Consumer 3D printers: In 2021, the market size of China’s consumer 3D printers increased from 356 million yuan to 2.974 billion yuan in 2017, while the average price decreased from 3800 yuan to 02,200 yuan per unit. The breakthrough iteration of technology and materials makes the application scenarios of 3D printing penetrate from industrial level to consumer level.

References:

https://bambulab.com/zh/download

[1]Bauer, J., et al. (2023). A sinterless, low-temperature route to 3D print nanoscale optical-grade glass. Science.

[2]Angelini, T. E., et al. (2023). A silicone-based support material eliminates interfacial instabilities in 3D silicone printing. Science.

[3]Sun, T., et al. (2023). Machine learning–aided real-time detection of keyhole pore generation in laser powder bed fusion. Science.

[4]Wohlers Associates. (2021). Wohlers Report 2021.