BBST

BSST Team | ZWU

2024.6

1.Class Practice

(AUTODESK FUSION & SHAPR 3D)

Course → Material

1.Common materials in daily life

Laser holographic materials

are a new type of material widely used in packaging and

anti-counterfeiting printing. The raw materials used for laser

holographic films mainly include PVC, PET, OPP, BOPP, etc. The varieties

include laser aluminum coating, laser transparent polishing film, laser

hot stamping paper, laser transfer paper, etc. The colors include gold,

silver, red, blue, green, black, etc. Laser holographic materials

integrate laser holographic image anti-counterfeiting technology with

printing and decoration technologies such as hot stamping and molding,

which have good anti-counterfeiting effects. This not only improves the

decoration effect of the product, but also adds anti-counterfeiting

performance. In addition, laser holography technology is combined with

other technologies to produce products such as laser holography with

fluorescent anti-counterfeiting film, flexible transparent laser

holography anti-counterfeiting film, and atomic nucleus confidential

anti-counterfeiting laser holography film, which further improves the

quality and anti-counterfeiting effect of laser holography film.

2.Two new materials

Analysis of advantages and disadvantages of polyethylene insulation:

1. Advantages

(1) Lightweight: Polyethylene insulation board has a low density and weight, which can reduce building loads.

(2) Insulation: Polyethylene insulation board has good insulation performance and can reduce energy consumption.

(3) Waterproof and moisture-proof: Polyethylene insulation board has excellent waterproof and moisture-proof properties, which can reduce leakage.

(4) Easy to construct: The construction of polyethylene insulation board is simple and fast, which can shorten the construction period.

(1) Lightweight: Polyethylene insulation board has a low density and weight, which can reduce building loads.

(2) Insulation: Polyethylene insulation board has good insulation performance and can reduce energy consumption.

(3) Waterproof and moisture-proof: Polyethylene insulation board has excellent waterproof and moisture-proof properties, which can reduce leakage.

(4) Easy to construct: The construction of polyethylene insulation board is simple and fast, which can shorten the construction period.

2. Disadvantages

(1) Easy to age: Polyethylene insulation boards are prone to aging over time, resulting in a decrease in insulation effectiveness.

(2) Flammable: Polyethylene insulation board is flammable, and safety precautions should be taken during construction.

(1) Easy to age: Polyethylene insulation boards are prone to aging over time, resulting in a decrease in insulation effectiveness.

(2) Flammable: Polyethylene insulation board is flammable, and safety precautions should be taken during construction.

Reference link for laser holographic materials:

【二维码防伪标签的技术原理,制作过程及防伪效果】https://mr.baidu.com/r/1lrpmwDQmbK?f=cp&rs=194211003&ruk=nkomwqMWdZ5oHqM2DexJvg&u=25ce757606f17bf6

【二维码防伪标签的技术原理,制作过程及防伪效果】https://mr.baidu.com/r/1lrpmwDQmbK?f=cp&rs=194211003&ruk=nkomwqMWdZ5oHqM2DexJvg&u=25ce757606f17bf6

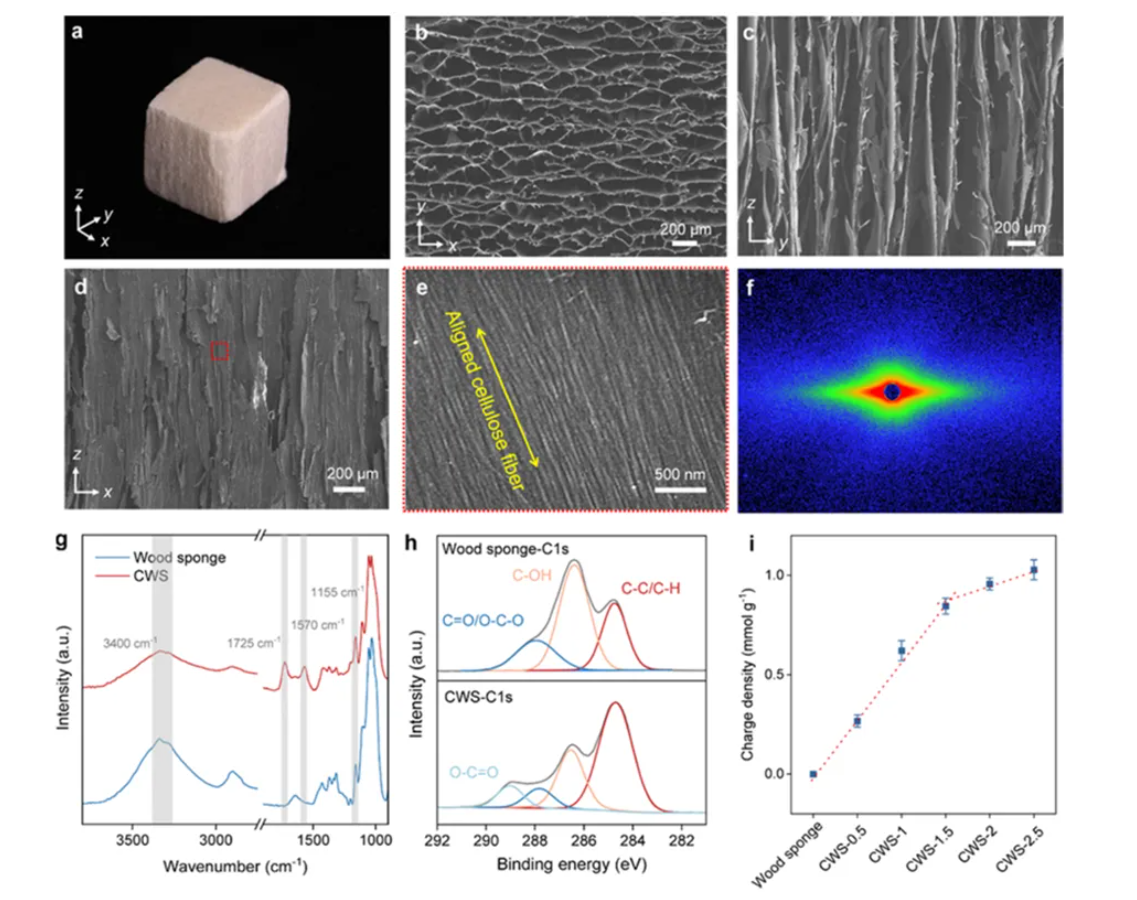

When woodworking wood, due to the large amount of wood dust, N95 grade

masks are sufficient

After inhaling wood dust, it is prone to respiratory and pulmonary inflammation. And it's very painful, so be sure to take good respiratory protection measures.

To prevent lung injury, in addition to dust reduction and sealing in the work environment, individuals need to scientifically choose dust masks.

Dust masks, as special labor protection equipment, must be certified by GB2626-2006.

1. Therefore, when choosing a mask, it is also necessary to choose according to the national standard. In the national standard, for dust and oily particles, protective masks are divided into oil proof (oil smoke, oil mist, dust, smoke, mist, microorganisms, represented by KP) and dust proof (dust, smoke, mist, microorganisms). For dust prevention, there are three levels of protection: KN100, KN95, and KN90. The protection rates for ultrafine dust are ≥ 99.97%,>95%, and>90%, respectively.

2. Masks are divided into disposable, replaceable filter type half masks, and full face masks. For long-term occupational protection use, especially in environments with high dust concentration, heavy smoke and other ultra-fine particles, it is recommended to use a replaceable filter cotton type half face mask. Disposable masks are mostly of no size and are relatively low-grade.

3. Mask materials include silicone, plastic, etc. Silicone materials are relatively soft and comfortable, with low facial pressure.

4. The size of the mask is divided according to the national standard, which is particularly important. Many masks are not numbered, and the effect will vary from person to person.

5. There are two types of masks: covering the mouth, nose, and jaw. The second type has a large contact mask, good sealing, and low pressure.

6. Do not ignore respiratory protection. Using fake and inferior masks, gauze, towels, etc. as masks can easily lead to the occurrence of lung diseases. At present, some common N100 level dust masks can ensure protection while breat

After inhaling wood dust, it is prone to respiratory and pulmonary inflammation. And it's very painful, so be sure to take good respiratory protection measures.

To prevent lung injury, in addition to dust reduction and sealing in the work environment, individuals need to scientifically choose dust masks.

Dust masks, as special labor protection equipment, must be certified by GB2626-2006.

1. Therefore, when choosing a mask, it is also necessary to choose according to the national standard. In the national standard, for dust and oily particles, protective masks are divided into oil proof (oil smoke, oil mist, dust, smoke, mist, microorganisms, represented by KP) and dust proof (dust, smoke, mist, microorganisms). For dust prevention, there are three levels of protection: KN100, KN95, and KN90. The protection rates for ultrafine dust are ≥ 99.97%,>95%, and>90%, respectively.

2. Masks are divided into disposable, replaceable filter type half masks, and full face masks. For long-term occupational protection use, especially in environments with high dust concentration, heavy smoke and other ultra-fine particles, it is recommended to use a replaceable filter cotton type half face mask. Disposable masks are mostly of no size and are relatively low-grade.

3. Mask materials include silicone, plastic, etc. Silicone materials are relatively soft and comfortable, with low facial pressure.

4. The size of the mask is divided according to the national standard, which is particularly important. Many masks are not numbered, and the effect will vary from person to person.

5. There are two types of masks: covering the mouth, nose, and jaw. The second type has a large contact mask, good sealing, and low pressure.

6. Do not ignore respiratory protection. Using fake and inferior masks, gauze, towels, etc. as masks can easily lead to the occurrence of lung diseases. At present, some common N100 level dust masks can ensure protection while breat

Steel parts undergo oxidation treatment to form a protective oxide film on

the surface, mainly composed of magnetic iron oxide (Fe3O4). The color of

the film is generally black or blue black, while cast steel and silicon

steel are brown or black brown.

The oxidation treatment methods include alkaline oxidation, alkali free oxidation, and acidic oxidation. Commonly used for the protection and decoration of machinery, precision instruments, instruments, weapons, and daily necessities.

The oxidation treatment methods include alkaline oxidation, alkali free oxidation, and acidic oxidation. Commonly used for the protection and decoration of machinery, precision instruments, instruments, weapons, and daily necessities.

4.ntroduce detail al materails in your final project

Plastic

:

Polyethylene(PE) is the most common type of plastic. It's used in

a variety of products, from plastic bags to water bottles, toys, and

even bulletproof vests. It's known for its durability and

flexibility.

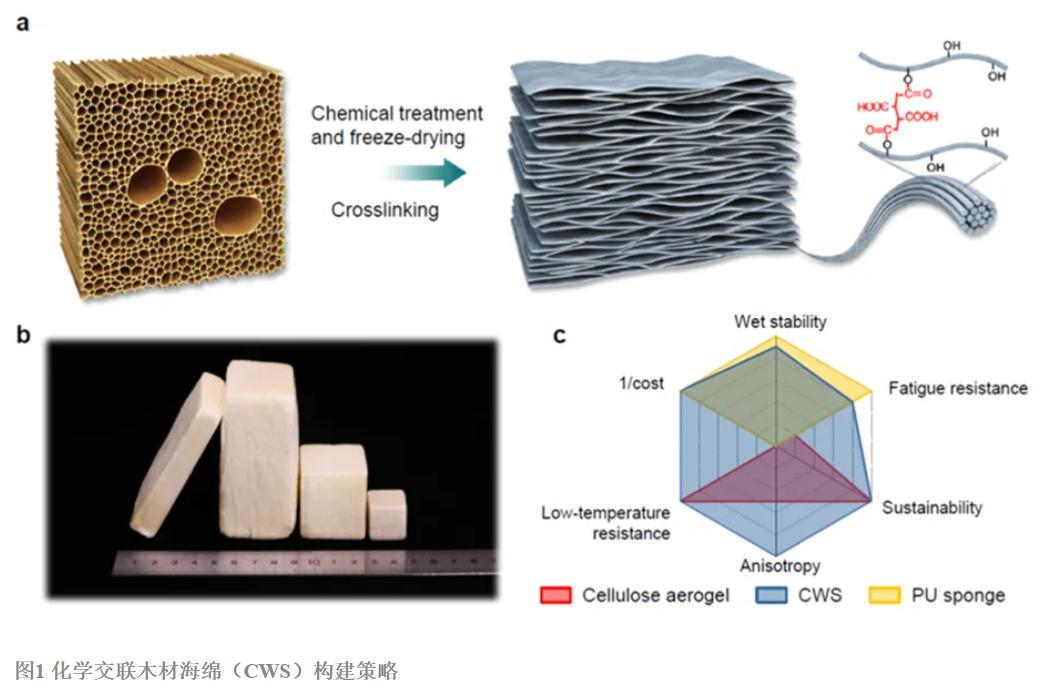

Wood sponge

is made by treating with chemicals, peeling off hemicellulose and

lignin, and can absorb oil from water. The absorption amount is 16-46

times its own weight, and it can be reused up to 10 times.This new type

of sponge surpasses all other sponges or absorbers we use today in terms

of capacity, quality, and reusability.Future development trend: Oil and

chemical spills have caused unprecedented damage to water bodies around

the world. As a green way to clean up the ocean, wooden sponges can

effectively solve this problem.

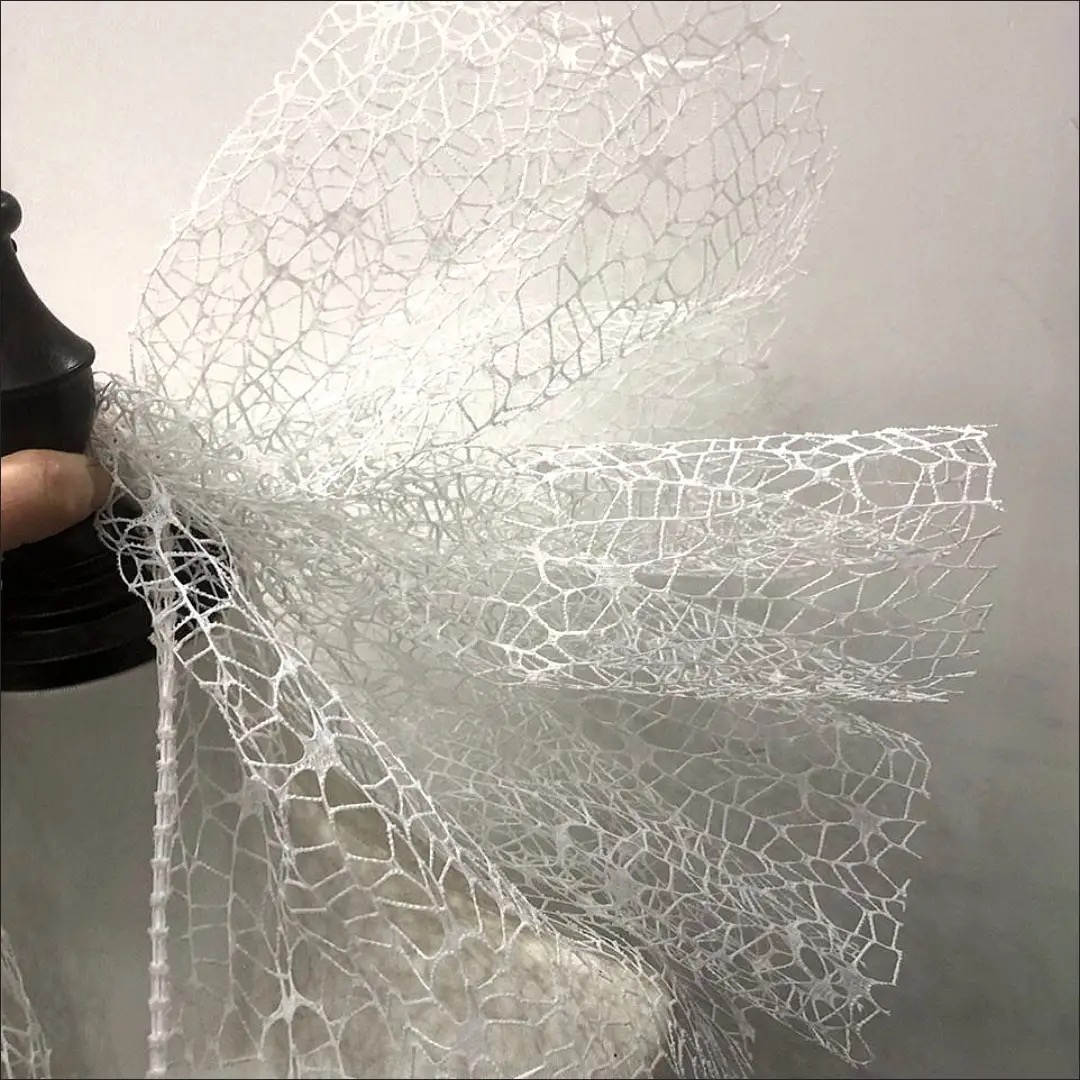

0.5mm iron wire

https://m.tb.cn/h.ggvfFUqvNdc0nDS?tk=VjjKWAgIQJA CZ0012

https://m.tb.cn/h.ggvfFUqvNdc0nDS?tk=VjjKWAgIQJA CZ0012

Cellophane

https://m.tb.cn/h.ggjQUMcGCYwR9NG?tk=lVkZWAgIAP5 HU9196

https://m.tb.cn/h.ggjQUMcGCYwR9NG?tk=lVkZWAgIAP5 HU9196

Textured paper

https://mobile.yangkeduo.com/goods.html?ps=J6dahIfztA

https://mobile.yangkeduo.com/goods.html?ps=J6dahIfztA

3D printing consumables

https://m.tb.cn/h.gT9CA9KyMIObupT?tk=KfGVWAgrky1

https://m.tb.cn/h.gT9CA9KyMIObupT?tk=KfGVWAgrky1