Material

iron

Basic attributes

Physical

Electrical conductivity: Iron has good electrical conductivity

Thermal conductivity: Iron also has good thermal conductivity

Ductility: Iron has some ductility and can be stretched into filaments or beaten into thin sheets

Ferromagnetism: Iron can be attracted to magnets and is ferromagnetic

Thermal conductivity: Iron also has good thermal conductivity

Ductility: Iron has some ductility and can be stretched into filaments or beaten into thin sheets

Ferromagnetism: Iron can be attracted to magnets and is ferromagnetic

Chemical properties

Compounds: Important compounds of iron include ferric oxide (Fe₂O₃),

ferric tetroxide (Fe₃O₄), ferric chloride (FeCl₃) and iron complexes

Presence in nature

Main minerals: hematite (mainly ferric oxide), magnetite (mainly ferric

oxide) and siderite (mainly ferrous carbonate), etc

Industrial preparation

Raw materials: The industrial preparation of iron is usually obtained by

smelting iron ore, coke and limestone in a blast furnace

Methods: including blast furnace method, direct reduction method, melt reduction method, plasma method, etc

Classification: According to the different carbon content, it can be divided into pig iron, wrought iron and steel

Methods: including blast furnace method, direct reduction method, melt reduction method, plasma method, etc

Classification: According to the different carbon content, it can be divided into pig iron, wrought iron and steel

Fields of application

Polyethylene

Polyethylene

Essential

Chemical formula: Formed by polymerization of ethylene monomer, the

chemical formula is usually -(CH2-CH2)n-.

Classification: Polyethylene is mainly divided into three categories: linear low-density polyethylene (LLDPE), low-density polyethylene (LDPE) and high-density polyethylene (HDPE).

Classification: Polyethylene is mainly divided into three categories: linear low-density polyethylene (LLDPE), low-density polyethylene (LDPE) and high-density polyethylene (HDPE).

Physical

Appearance: Polyethylene plastics are usually milky white, odorless,

odorless, non-toxic, and waxy particles with a dull surface.

Density: Different types of polyethylene have different densities. For example, LDPE has a lower density of about 0.918 g/cm³; The density of HDPE is higher, about 0.945~0.96 g/cm3.

Melting Point: The melting point also varies depending on the species. The melting point of LDPE is low, about 105~115 °C; HDPE, on the other hand, has a higher melting point, about 125~137°C.

Other characteristics: polyethylene plastic has excellent low temperature resistance (the lowest use temperature can reach -100~-70 °C), good chemical stability, and can resist the erosion of most acids and alkalis (not resistant to acids with oxidizing properties). In addition, it also has excellent resistance to most domestic and industrial chemicals, insoluble in general solvents at room temperature, low water absorption, and excellent electrical insulation

Density: Different types of polyethylene have different densities. For example, LDPE has a lower density of about 0.918 g/cm³; The density of HDPE is higher, about 0.945~0.96 g/cm3.

Melting Point: The melting point also varies depending on the species. The melting point of LDPE is low, about 105~115 °C; HDPE, on the other hand, has a higher melting point, about 125~137°C.

Other characteristics: polyethylene plastic has excellent low temperature resistance (the lowest use temperature can reach -100~-70 °C), good chemical stability, and can resist the erosion of most acids and alkalis (not resistant to acids with oxidizing properties). In addition, it also has excellent resistance to most domestic and industrial chemicals, insoluble in general solvents at room temperature, low water absorption, and excellent electrical insulation

Fields of application

Packaging industry: polyethylene plastic is mainly used to make plastic

wrap, vest plastic bags, plastic food bags, etc. Due to its non-toxic,

tasteless and odorless characteristics, it is widely used in the field

of food packaging.

Agriculture: It is used to make agricultural mulch film to increase soil temperature, maintain soil moisture, and promote crop growth.

Construction: In the construction sector, polyethylene plastic can be used to make waterproofing membranes, pipes, etc.

Others: In addition, polyethylene plastic is also used to make everyday products such as baby bottles, pails, and kettles, as well as insulation and sheaths for wires and cables

Agriculture: It is used to make agricultural mulch film to increase soil temperature, maintain soil moisture, and promote crop growth.

Construction: In the construction sector, polyethylene plastic can be used to make waterproofing membranes, pipes, etc.

Others: In addition, polyethylene plastic is also used to make everyday products such as baby bottles, pails, and kettles, as well as insulation and sheaths for wires and cables

Production process

The production of polyethylene plastics mainly uses high-pressure and

low-pressure methods. The high-pressure method for the production of

LDPE is the most technologically mature method in the production of PE

resin, while the low-pressure method is mainly used for the production

of HDPE and LLDPE. These production processes require specific catalysts

and reaction conditions to ensure product quality and performance.

Definition

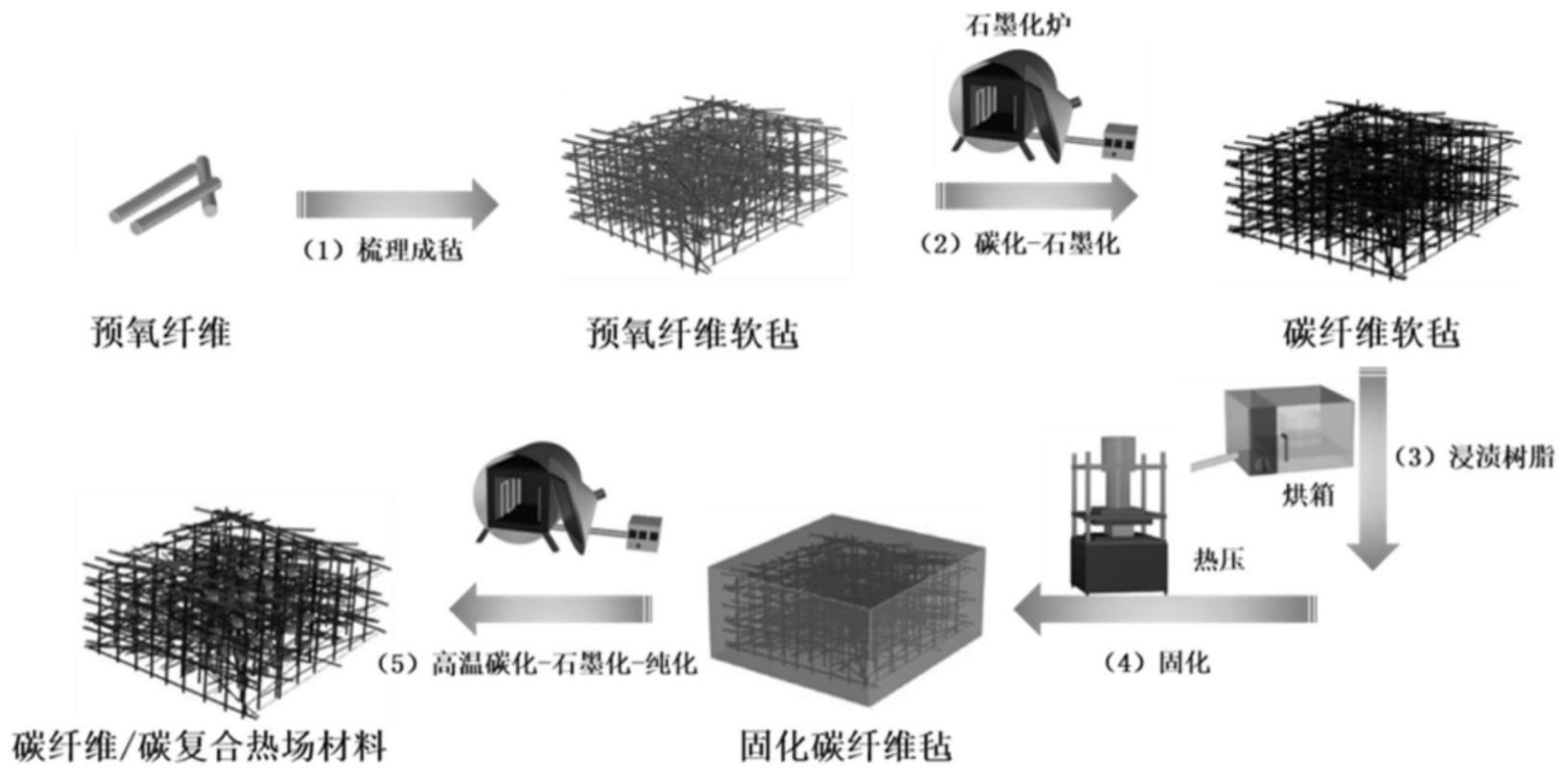

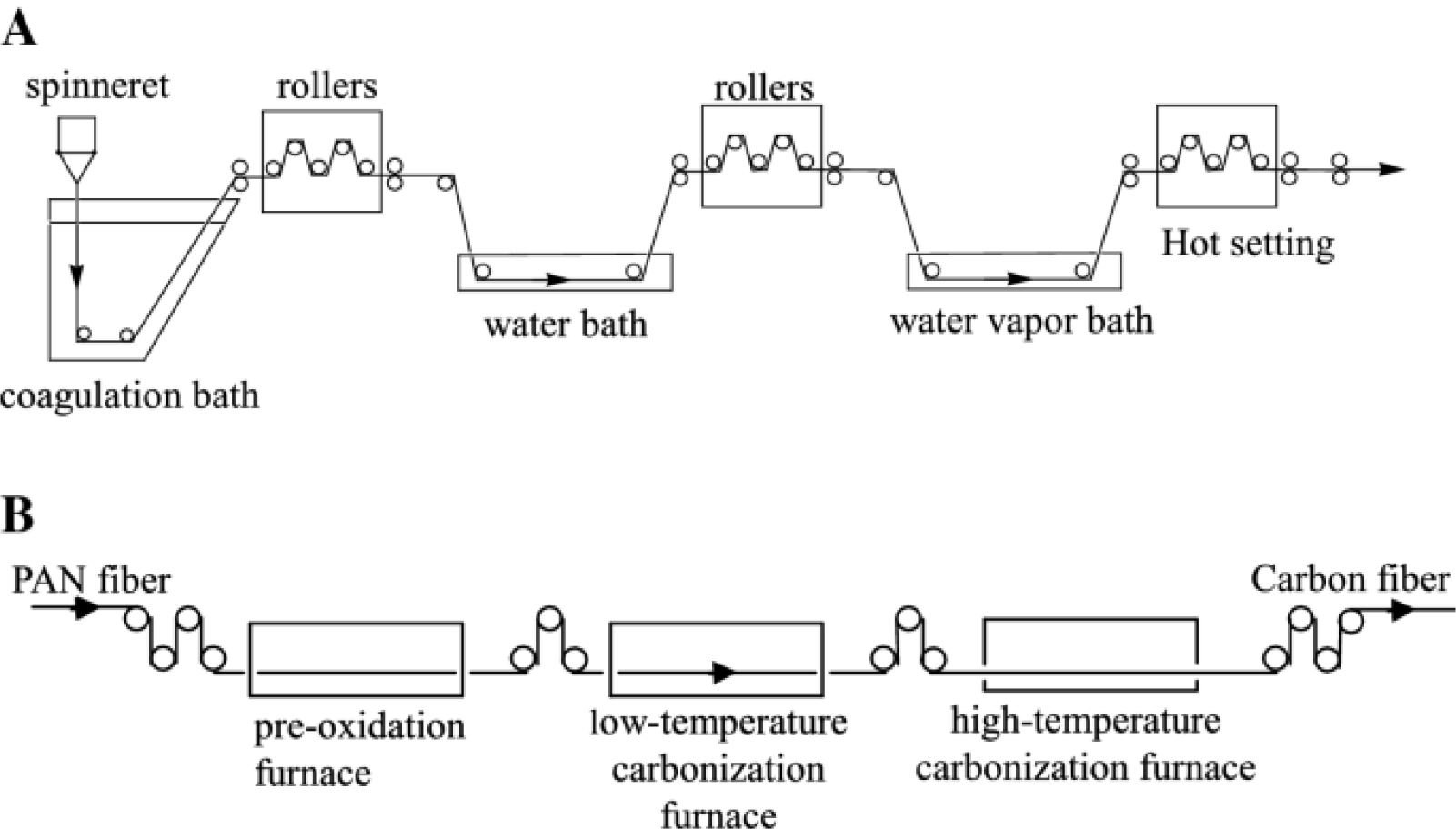

Carbon fiber reinforced polymer (CFRP) is a high-performance composite

material, which is mainly composed of carbon fiber as a reinforcing

material and resin (such as epoxy resin) as a matrix material.

Characteristic

Fields of application

Aerospace: Due to its lightweight and high-strength characteristics,

CFRP is widely used in the aerospace field, such as aircraft fuselage,

wings, tails, etc.

Automotive industry: CFRP is used in automotive manufacturing to reduce body weight, improve fuel efficiency, and enhance body structural strength.

Sports equipment: Sports equipment such as high-performance bicycles, golf clubs, and tennis rackets are often manufactured with CFRP to reduce weight and improve performance

Automotive industry: CFRP is used in automotive manufacturing to reduce body weight, improve fuel efficiency, and enhance body structural strength.

Sports equipment: Sports equipment such as high-performance bicycles, golf clubs, and tennis rackets are often manufactured with CFRP to reduce weight and improve performance

Construction & Fabrication

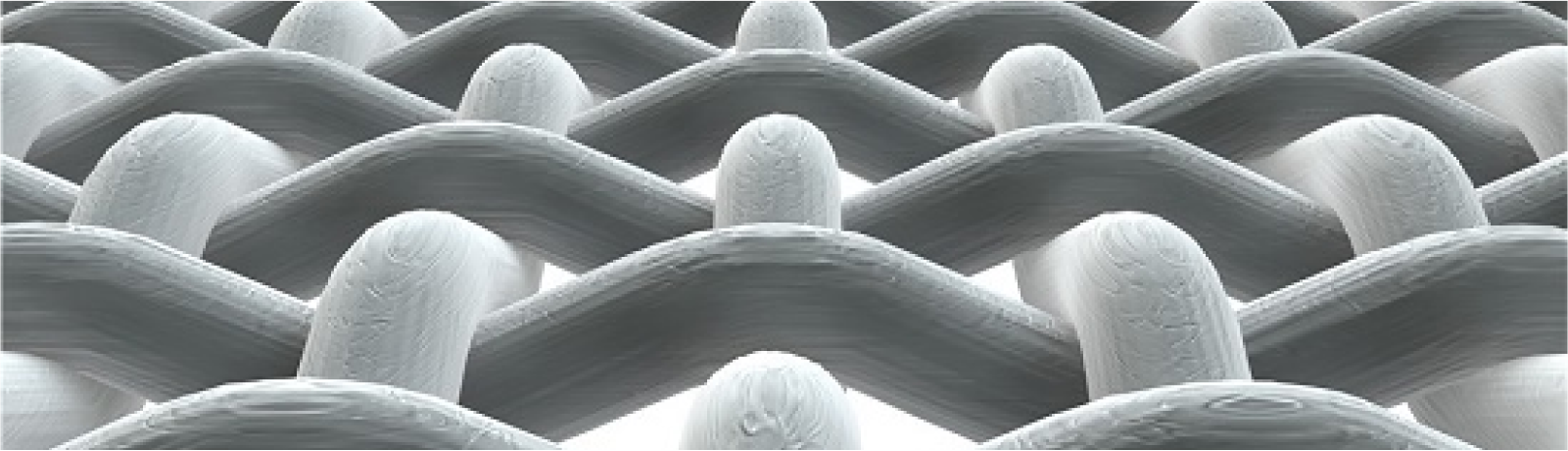

CFRP is composed of carbon fiber and resin matrix through lamination,

injection molding, pultrusion and other processes.

Carbon fibers exist in the form of fiber bundles or fabrics that provide strength and stiffness to composite materials; The resin matrix holds the carbon fibers in place and transmits the load.

Carbon fibers exist in the form of fiber bundles or fabrics that provide strength and stiffness to composite materials; The resin matrix holds the carbon fibers in place and transmits the load.

Trends

New materials

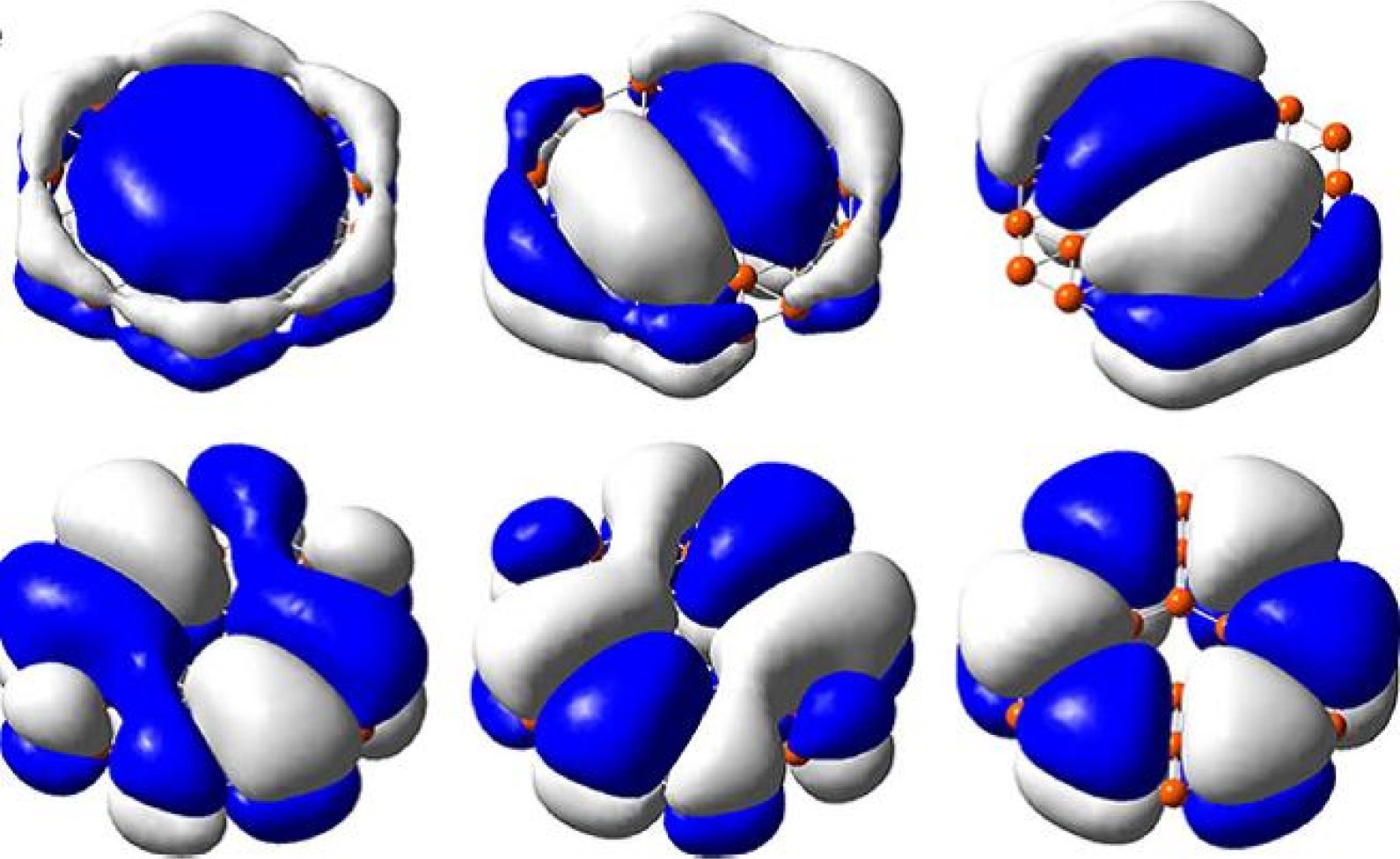

1 Boronene material

Characteristic

High electrical conductivity: Boron ink has excellent electrical

conductivity and is expected to be used in high-performance electronic

devices.

High strength: Its mechanical strength is also extremely high, making it an ideal high-strength material.

Chemical stability: It shows good chemical stability at room temperature and is not easy to be oxidized or corroded.

High strength: Its mechanical strength is also extremely high, making it an ideal high-strength material.

Chemical stability: It shows good chemical stability at room temperature and is not easy to be oxidized or corroded.

Application prospects

Energy storage: It can be used to develop high-performance batteries and

supercapacitors.

Electronic devices: Used as conductive channels or electrode materials in electronic devices to improve device performance.

Composite materials: as a reinforcing phase, improve the mechanical properties and electrical conductivity of composite materials

Electronic devices: Used as conductive channels or electrode materials in electronic devices to improve device performance.

Composite materials: as a reinforcing phase, improve the mechanical properties and electrical conductivity of composite materials

Definition

Graphene is a new nanomaterial with the thinnest, hardest, and strongest

electrical and thermal conductivity discovered so far, and is known as

"black gold" and "king of new materials".

Characteristic

Application prospects

New energy field: Graphene has huge application potential in the lithium

battery and supercapacitor market, and the market size is expected to

exceed tens of billions of yuan.

Composite materials: Graphene is also widely used in plastics, rubber, coatings, conductive inks and other fields

Composite materials: Graphene is also widely used in plastics, rubber, coatings, conductive inks and other fields

Post-processing methods of wood

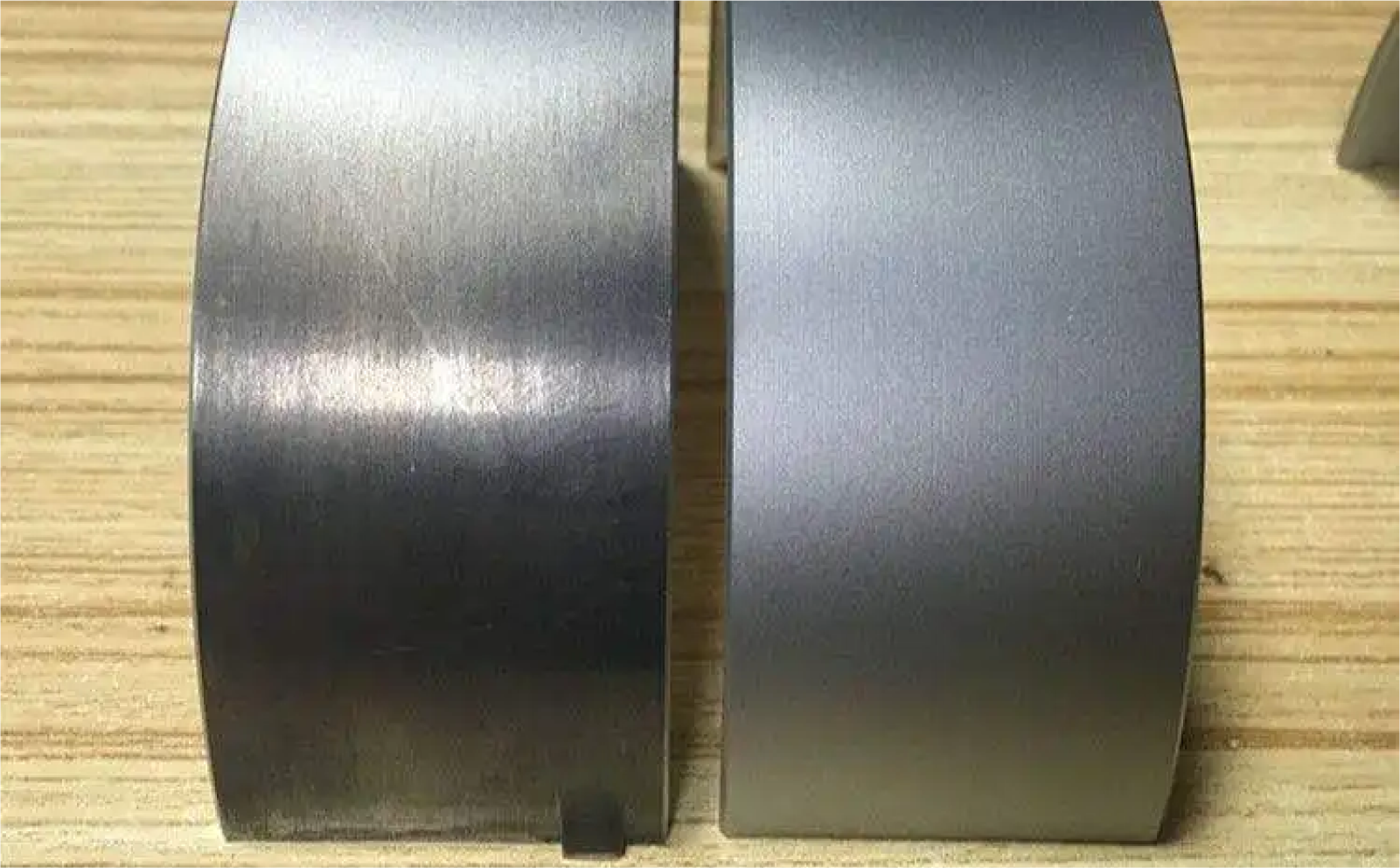

Sanding:

Sanding is an important step in the post-processing of wood to achieve a smooth, even surface. It involves the use of sanding tools or machines with abrasive materials to remove rough edges, bumps, or scratches from the surface of the wood. Grinding can be done manually or with power tools, depending on the size and complexity of the workpiece. After sanding, the wood can be further surface treated with dyes, varnishes, or paints.

Sanding is an important step in the post-processing of wood to achieve a smooth, even surface. It involves the use of sanding tools or machines with abrasive materials to remove rough edges, bumps, or scratches from the surface of the wood. Grinding can be done manually or with power tools, depending on the size and complexity of the workpiece. After sanding, the wood can be further surface treated with dyes, varnishes, or paints.