Materails

4AOL

2. Introduce 2 new materials;

4. Introduce detail all materails in our final project

1-2 plastic--Polyethylene

1-3 composite materials--Wood plastic composites

2-1 Milk Plastic

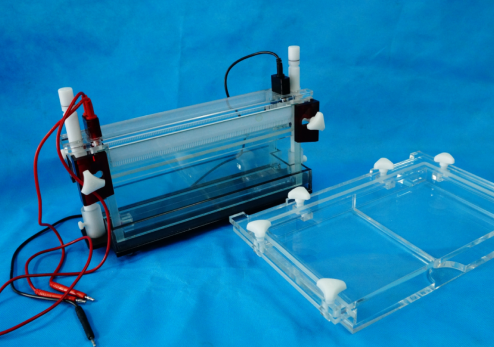

4-1 Acrylic (device housing)

4-2 Plastics(塑料)/plastics(塑胶)

---Miniature tree model & Miniatures of the house

---Miniature tree model & Miniatures of the house

4-3 Sandpaper--- miniature roads

4-4 PC pipe(Polycarbonate pipe)---Blowpipe

2-2

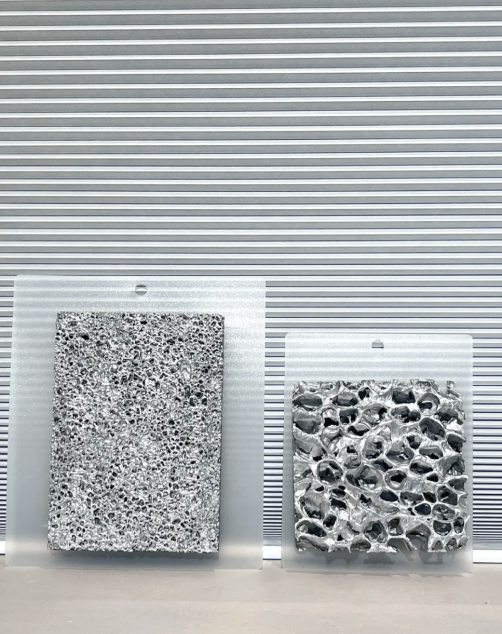

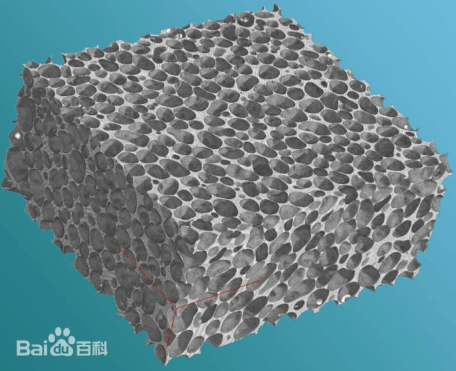

Aluminum Foam Sheet

3-1

Surface treatment process

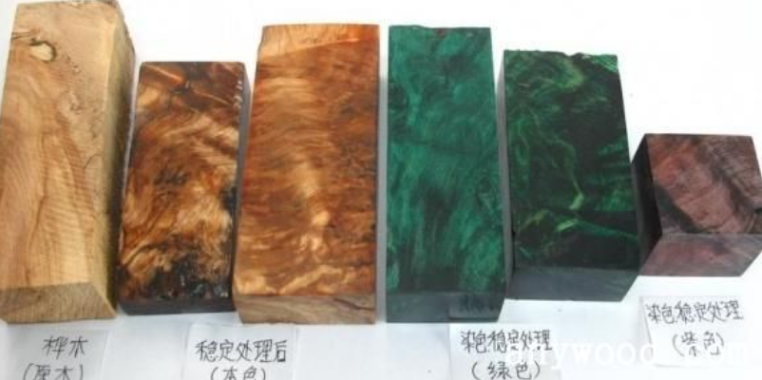

3-2 Wood surface treatment process

a.

Polyethylene

Chemical name: polyethylene

Polyethylene is a thermoplastic resin prepared by polymerization of ethylene, and also includes copolymers of ethylene and a small amount of olefins. Polyethylene is one of the five major synthetic resins, and it is the variety with the largest production capacity and the largest import volume of synthetic resins in China.

b .the performance of polyethylene :

1. General performance Polyethylene is a white waxy translucent material, odorless, tasteless, non-toxic, insoluble in general solvents at room temperature, and has low water absorption. PE is flammable, waxy when burned, and is accompanied by molten dripping.

2. Mechanical properties:

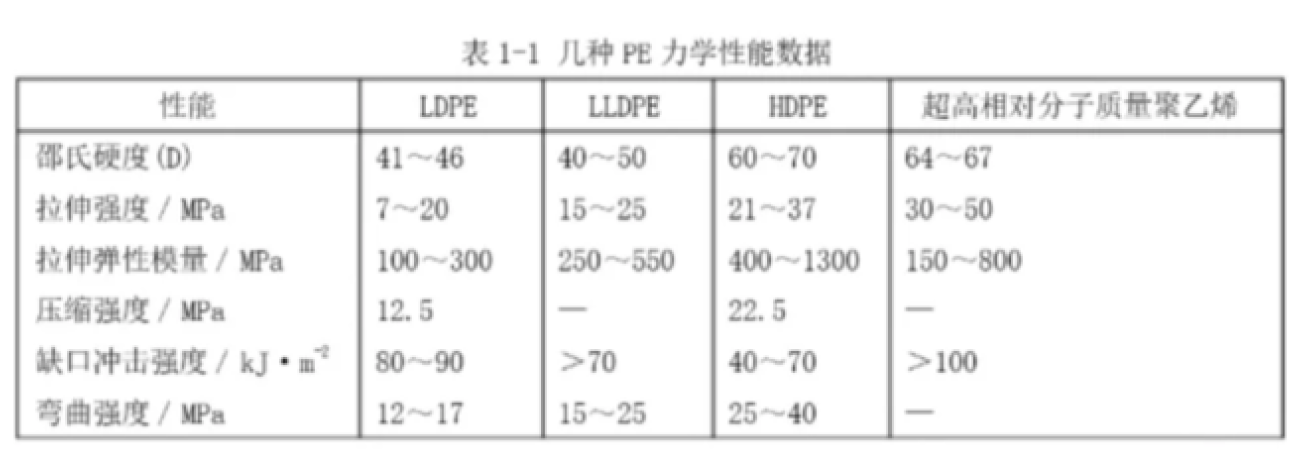

PE is a typically soft and tough polymer. Except for the high impact strength, the absolute value of other mechanical properties is low in plastic materials. With the increase of PE density, the mechanical properties except toughness are improved. The mechanical properties of several types of PE are shown in Table 1-1.

Chemical name: polyethylene

Polyethylene is a thermoplastic resin prepared by polymerization of ethylene, and also includes copolymers of ethylene and a small amount of olefins. Polyethylene is one of the five major synthetic resins, and it is the variety with the largest production capacity and the largest import volume of synthetic resins in China.

b .the performance of polyethylene :

1. General performance Polyethylene is a white waxy translucent material, odorless, tasteless, non-toxic, insoluble in general solvents at room temperature, and has low water absorption. PE is flammable, waxy when burned, and is accompanied by molten dripping.

2. Mechanical properties:

PE is a typically soft and tough polymer. Except for the high impact strength, the absolute value of other mechanical properties is low in plastic materials. With the increase of PE density, the mechanical properties except toughness are improved. The mechanical properties of several types of PE are shown in Table 1-1.

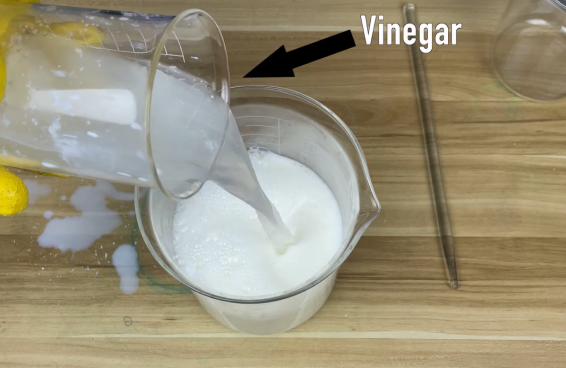

First, heat the milk to about 80 degrees

Vinegar is added to make the milk pH level acidic

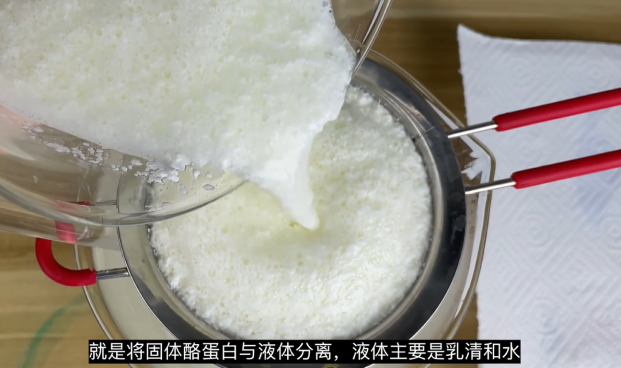

Solid casein is separated from the liquid, which is mainly whey and water

Pinch them into the shape you want

Dry the casein with a paper towel to allow it to be molded

a.Definition:

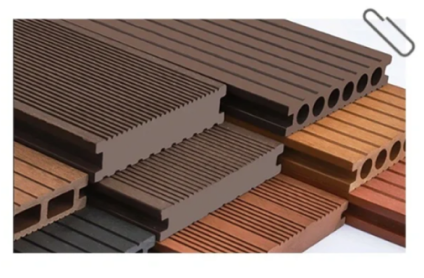

It is a new type of composite material that has flourished at home and abroad in recent years, which refers to the use of polyethylene, polypropylene and polyvinyl chloride instead of the usual resin adhesive, and then through extrusion, molding, injection molding and other plastic processing technologies to produce plates or profiles.

b.Scope of application:

One of the most important uses of wood-plastic composites is the application of replacing solid wood in various fields, among which the most widely used is in building products, accounting for 75% of the total number of wood-plastic composite products. Wood-plastic composites are mainly used in flower boxes, tree ponds, fences, garbage cans, stools, chair strips, signs, etc.

c.Key features:

1. Good processing performance;

2. Good strength performance;

3. It has water resistance, corrosion resistance, and long service life;

4. Excellent adjustable performance;

5. It has ultraviolet light stability and good colorability ;

6. It can turn waste into treasure and can be 100% recycled and reproduced. It can be decomposed, will not cause "white pollution", and is a real green and environmentally friendly product;

7. Wide range of raw materials;

8. It can be made into any shape and size according to needs;

It is a new type of composite material that has flourished at home and abroad in recent years, which refers to the use of polyethylene, polypropylene and polyvinyl chloride instead of the usual resin adhesive, and then through extrusion, molding, injection molding and other plastic processing technologies to produce plates or profiles.

b.Scope of application:

One of the most important uses of wood-plastic composites is the application of replacing solid wood in various fields, among which the most widely used is in building products, accounting for 75% of the total number of wood-plastic composite products. Wood-plastic composites are mainly used in flower boxes, tree ponds, fences, garbage cans, stools, chair strips, signs, etc.

c.Key features:

1. Good processing performance;

2. Good strength performance;

3. It has water resistance, corrosion resistance, and long service life;

4. Excellent adjustable performance;

5. It has ultraviolet light stability and good colorability ;

6. It can turn waste into treasure and can be 100% recycled and reproduced. It can be decomposed, will not cause "white pollution", and is a real green and environmentally friendly product;

7. Wide range of raw materials;

8. It can be made into any shape and size according to needs;

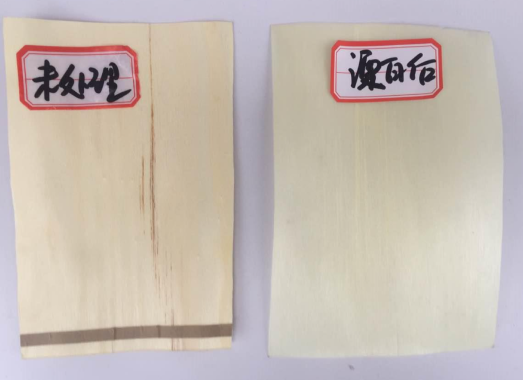

a.[Sanding]:

The process of grinding back and forth in the direction of the wood grain is carried out on the surface of the wood with sandpaper to make the wood surface smoother.

There are mechanical sanding and manual sanding

The process of grinding back and forth in the direction of the wood grain is carried out on the surface of the wood with sandpaper to make the wood surface smoother.

There are mechanical sanding and manual sanding

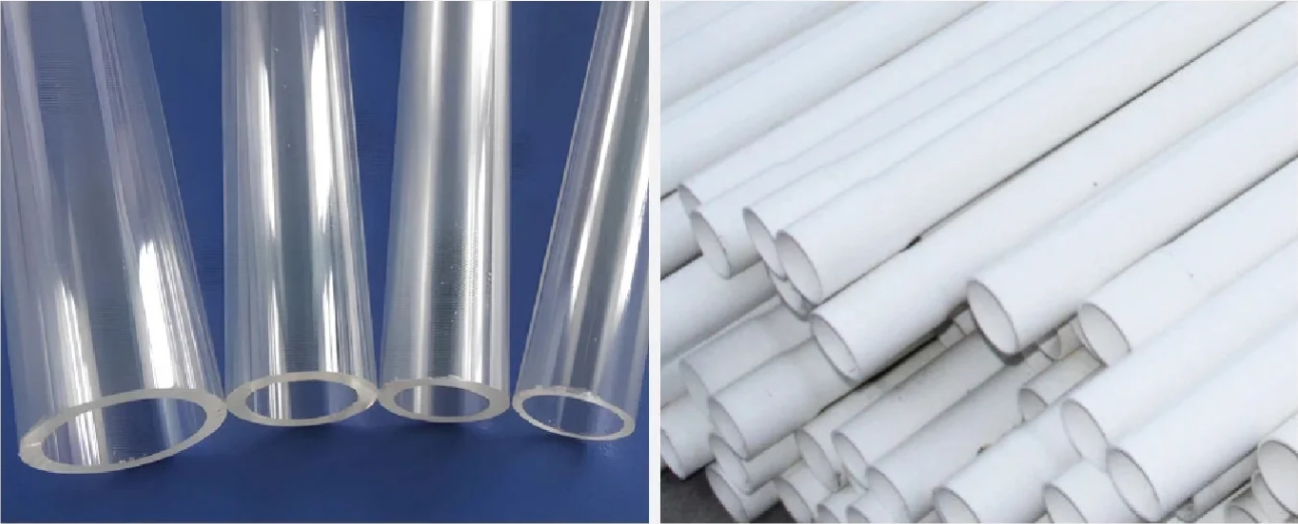

(Comparative analysis with PVC pipes)

1. The ingredients are different

● PC Pipe: The main ingredient is polycarbonate resin (a polymer containing a carbonate base in the molecular chain)

● PVC Pipe: The main ingredient is polyvinyl chloride resin (a thermoplastic polymer made from the polymerization of vinyl chloride monomer (VCM)).

● PC Pipe: The main ingredient is polycarbonate resin (a polymer containing a carbonate base in the molecular chain)

● PVC Pipe: The main ingredient is polyvinyl chloride resin (a thermoplastic polymer made from the polymerization of vinyl chloride monomer (VCM)).

2. the appearance is different

● PC Pipe: The PC tube has good light transmittance and good transparency, which is suitable for scenarios where the fluid state needs to be observed. (However, when the PC tube is used as a threading tube, it is generally made opaque and milky white due to performance considerations.)

● PVC Pipe: PVC pipes are generally opaque or translucent, with poor light transmittance, and the inside of the pipe cannot be directly observed.

● PC Pipe: The PC tube has good light transmittance and good transparency, which is suitable for scenarios where the fluid state needs to be observed. (However, when the PC tube is used as a threading tube, it is generally made opaque and milky white due to performance considerations.)

● PVC Pipe: PVC pipes are generally opaque or translucent, with poor light transmittance, and the inside of the pipe cannot be directly observed.

3.the impact resistance is different

● PC tube: It has excellent impact resistance and is a high-toughness material that retains good impact resistance even under extreme temperature conditions.

● PVC Pipe: The impact resistance is poor, and it is easy to crack or break when impacted, especially in low temperature environments.

4.the bending strength is different

● PC tube: It has good bending strength and can withstand a certain degree of bending and deformation without breaking.

● PVC Pipe: The bending strength is relatively low, and it is easy to deform and crack when subjected to external forces;

5. The applicable temperature range is different

● PC tube: It has a wide temperature range and is generally able to operate normally from -40°C to -130°C. (Generally starts to soften at around 140°C)

● PVC Pipe: It is generally suitable for temperatures ranging from 0°C to 60°C.

6. the weather resistance is different

● PC tube: It has good UV resistance, is not easy to age and become brittle under sun exposure, and is suitable for long-term outdoor use.

● PVC Pipe: It is less resistant to ultraviolet rays and can age, become brittle, and discolored when exposed to sunlight for a long time.

7. Different application fields

● PC tube: It is often used to protect pipes with wires and cables in high-strength, impact-resistant environments, and is widely used in lighting, medical, electronics, and other fields due to its highly transparent properties. ● PVC Pipe: It is mainly used for drainage, sewage and farmland irrigation, wire and cable protection in residential, commercial buildings and industrial facilities.

8. The cost is different

● PC tube: Polycarbonate resin is a high-performance plastic, the market price is high, and the production process is relatively complex, so the cost is high.

● PVC Pipe: Polyvinyl chloride resin is a common plastic raw material, the price is relatively stable, and the production process is relatively simple, so the cost is low. The above nine points are the overall comparison of PC pipe (polycarbonate pipe) and PVC pipe (hard PVC pipe), in addition, for the flame retardant performance of the two, I personally feel that the flame retardant is quite strong, and it can be extinguished from the fire, so the flame retardant performance is not listed separately for comparison.

● PC tube: It has excellent impact resistance and is a high-toughness material that retains good impact resistance even under extreme temperature conditions.

● PVC Pipe: The impact resistance is poor, and it is easy to crack or break when impacted, especially in low temperature environments.

4.the bending strength is different

● PC tube: It has good bending strength and can withstand a certain degree of bending and deformation without breaking.

● PVC Pipe: The bending strength is relatively low, and it is easy to deform and crack when subjected to external forces;

5. The applicable temperature range is different

● PC tube: It has a wide temperature range and is generally able to operate normally from -40°C to -130°C. (Generally starts to soften at around 140°C)

● PVC Pipe: It is generally suitable for temperatures ranging from 0°C to 60°C.

6. the weather resistance is different

● PC tube: It has good UV resistance, is not easy to age and become brittle under sun exposure, and is suitable for long-term outdoor use.

● PVC Pipe: It is less resistant to ultraviolet rays and can age, become brittle, and discolored when exposed to sunlight for a long time.

7. Different application fields

● PC tube: It is often used to protect pipes with wires and cables in high-strength, impact-resistant environments, and is widely used in lighting, medical, electronics, and other fields due to its highly transparent properties. ● PVC Pipe: It is mainly used for drainage, sewage and farmland irrigation, wire and cable protection in residential, commercial buildings and industrial facilities.

8. The cost is different

● PC tube: Polycarbonate resin is a high-performance plastic, the market price is high, and the production process is relatively complex, so the cost is high.

● PVC Pipe: Polyvinyl chloride resin is a common plastic raw material, the price is relatively stable, and the production process is relatively simple, so the cost is low. The above nine points are the overall comparison of PC pipe (polycarbonate pipe) and PVC pipe (hard PVC pipe), in addition, for the flame retardant performance of the two, I personally feel that the flame retardant is quite strong, and it can be extinguished from the fire, so the flame retardant performance is not listed separately for comparison.

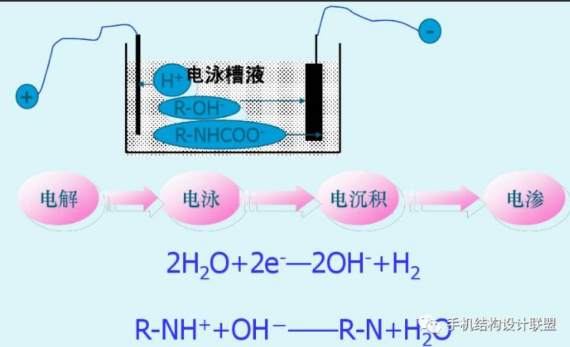

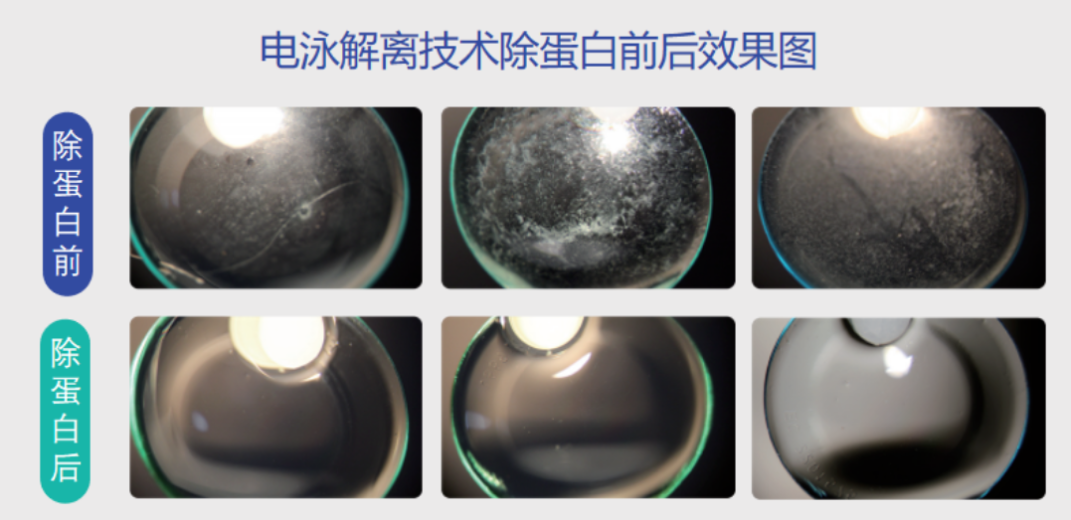

Effect of electrophoretic dissociation technique before and after protein

removal

A brief introductory video:

http://baike.baidu.com/l/lVFiRlkp

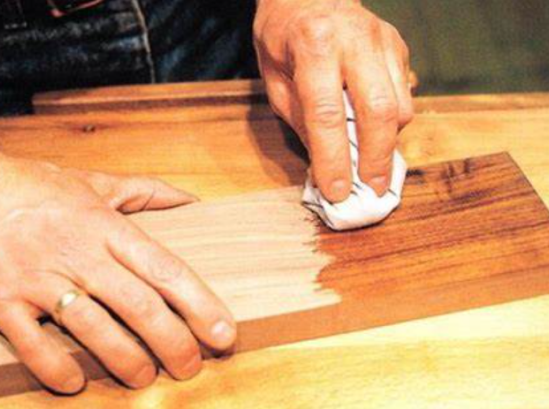

b.[Polished]:

Remove the surface of the wood products stained by glue marks, oil stains and other dirt, first polish them with sandpaper, and then scrub them with cotton yarn dipped in gasoline. If the cleaning is not clean, use a fine planer to clean the surface.

Remove the surface of the wood products stained by glue marks, oil stains and other dirt, first polish them with sandpaper, and then scrub them with cotton yarn dipped in gasoline. If the cleaning is not clean, use a fine planer to clean the surface.

c.[Decolorization]:

The wood is bleached with oxidation-reduction chemicals.

Commonly used decolorizing agents: hydrogen peroxide, sodium hypochlorite, sodium peroxide

The wood is bleached with oxidation-reduction chemicals.

Commonly used decolorizing agents: hydrogen peroxide, sodium hypochlorite, sodium peroxide

d.[Stain]:Chemically or otherwise influencing the substance itself to

color it, so that the object takes on the colors that people need.

There are two types: water dyeing and wine dyeing.

There are two types: water dyeing and wine dyeing.